|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 5 Sets Per Month |

IEC 62196-3 Vehicle Connector And Plug Mechanical Endurance Test Equipment For EV Charging

Applied standard & clauses:

IEC 62196-3: 2022 clause 22 and 23.

IEC 62196-1: 2022 clause 22, 23.2, 23.3, fig 15, table 8 and table 9.

Product information:

This test equipment meets the requirements of IEC 62196-3: 2020 clause 22 and 23, IEC62196-1: 2020 clause 22 and clause 23, IEC60309-1: 2012 clause 20 and clause 21, etc.

It is used to verify whether electrical accessories such as electric vehicle charging interfaces, industrial plugs, socket-outlets and couplers can withstand the mechanical, electrical and thermal stresses that occurred during normal operation without excessive wear or other harmful effects.

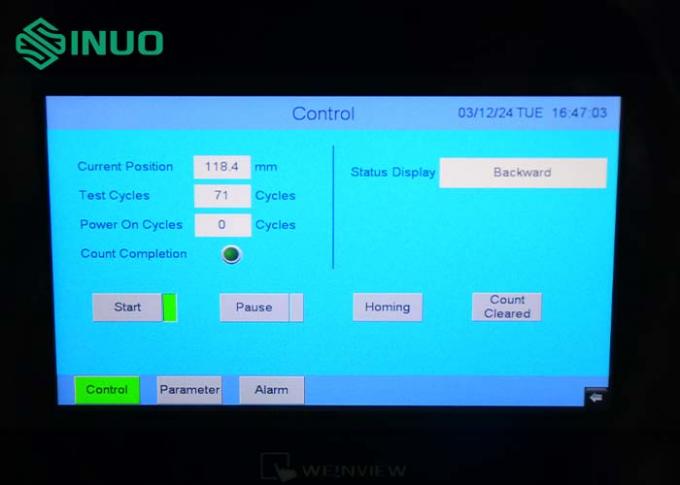

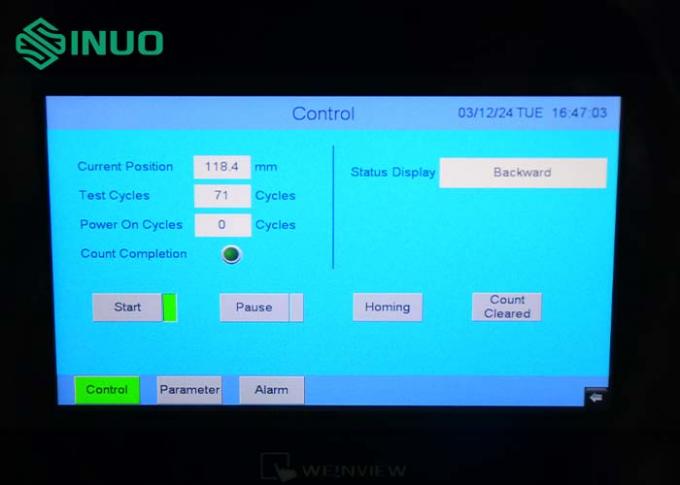

The servo motor drives the mechanism to make the test samples repeat insertion and withdrawal actions. An external load can be used for the breaking capacity test. The power on / off time, test speed, stroke, and angle can all be preset on the touch screen.

Technical Parameters:

| Test Station | Single, can be customized |

| Electrical Control Method | PLC intelligent integrated control, with color humanized touch screen |

| Drive Mode | Servo motor drive |

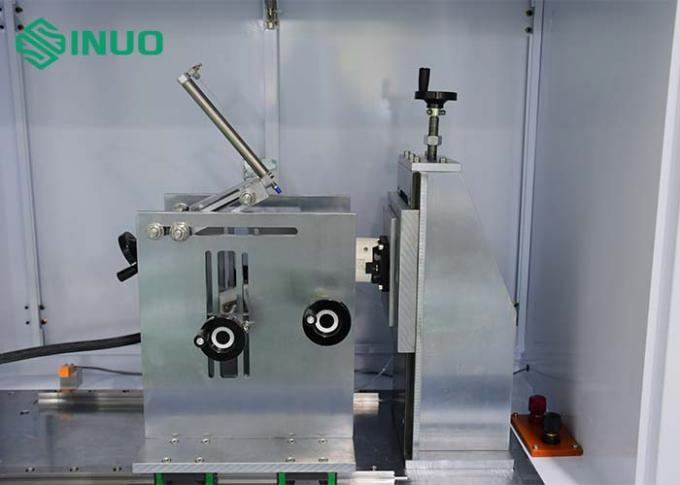

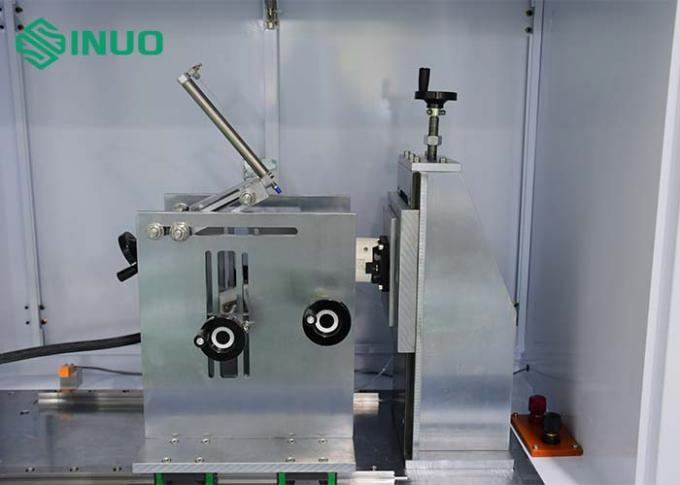

| Sample Clamping Method | Mechanical clamping, the position of clamping point can be adjustable along the 3-axis fixture |

| Linear Stroke | 0-100mm, can be preset (the spacing between test plug and test socket≥ 50mm) |

| Conduction Time | 0-99.9s, can be preset (electrical contact should be maintained no more than 4s, no less than 2s) |

| Speed of Insertion and Separation | 0-0.85m/s can be preset, default (0.8±0.1) m/s |

| Test Cycles | 0~999999 cycles, can be preset (A stroke is an insertion or a withdrawal of a plug or vehicle connector with its mating accessory. A cycle is composed of two strokes, one for insertion and one for withdrawal.) |

| Test Frequency | 0-10 cycles/min, can be preset (3.75cycles/min=7.5 stoke/min) |

| Load Power | External, providing standard required voltage, current and power factor, recommended to work with the load cabinet SN224-300V80A |

| Test Contents |

Appliance coupler/charging interface breaking capacity test Appliance coupler / charging interface normal operating life test |

| Detection Function | An open circuit alarm can be realized during testing under load, and the cycles can be recorded real in time. |

| Safety Protection | Ground protection, short circuit protection |

| Power Supply | Single phase AC220V±10%, 50/60Hz, 10A |

|

Equipment Dimension & Weight |

L 1430mm * W 600mm * H1620mm, approx. 180KGS |

A vehicle connector and plug mechanical endurance test machine is a specialized testing equipment used to assess the durability and mechanical performance of vehicle connectors and plugs. These connectors and plugs are crucial components in vehicle electrical systems, providing the interface for electrical connections between various vehicle components. The mechanical endurance test machine simulates the repeated mating and unmating cycles that these connectors and plugs may undergo during vehicle operation. Here are the key features and components typically found in this test machine:

Test Fixture: The machine includes a test fixture designed to securely hold and position the vehicle connector and plug being tested. The fixture allows for controlled mating and unmating motions without damaging the connectors or plugs.

Actuation Mechanism: The test machine incorporates an actuation mechanism that applies repeated mating and unmating cycles to the connectors and plugs. This mechanism can be programmed to simulate specific mating forces, insertion and extraction speeds, and cycle patterns.

Force Measurement: The machine is equipped with force measurement sensors or load cells to measure the mating and unmating forces applied during the test. This allows for evaluating the force required for proper connection and disconnection of the connectors and plugs.

Displacement Measurement: The test machine includes displacement measurement devices, such as linear encoders or displacement transducers, to measure the relative movement or displacement of the connectors and plugs during the mating and unmating cycles.

Cycle Counter and Timer: The machine is equipped with a cycle counter and timer to track the number of mating and unmating cycles completed and measure the duration of the test. This information helps evaluate the endurance and mechanical performance of the connectors and plugs over time.

Control System: The test machine incorporates a control system that allows users to set the desired test parameters, such as force levels, cycle patterns, and speed. The control system also ensures accurate and repeatable testing procedures.

Data Acquisition and Analysis: The test machine may have data acquisition capabilities to record and analyze the test results. This includes monitoring factors such as mating and unmating forces, displacements, and any signs of wear or failure observed during the test.

Safety Features: Safety considerations are implemented in the machine to protect operators and ensure safe testing procedures. These features may include emergency stop buttons, protective enclosures, and safety interlocks.

The vehicle connector and plug mechanical endurance test machine is crucial for manufacturers and quality control departments to ensure the reliability and durability of connectors and plugs in vehicle electrical systems. By subjecting the connectors and plugs to repeated mating and unmating cycles, this machine helps identify any weaknesses, wear, or damage that may occur over time. The test results enable manufacturers to improve the design and materials of the connectors and plugs, ensuring their long-term performance and reliability in vehicle applications.

|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 5 Sets Per Month |

IEC 62196-3 Vehicle Connector And Plug Mechanical Endurance Test Equipment For EV Charging

Applied standard & clauses:

IEC 62196-3: 2022 clause 22 and 23.

IEC 62196-1: 2022 clause 22, 23.2, 23.3, fig 15, table 8 and table 9.

Product information:

This test equipment meets the requirements of IEC 62196-3: 2020 clause 22 and 23, IEC62196-1: 2020 clause 22 and clause 23, IEC60309-1: 2012 clause 20 and clause 21, etc.

It is used to verify whether electrical accessories such as electric vehicle charging interfaces, industrial plugs, socket-outlets and couplers can withstand the mechanical, electrical and thermal stresses that occurred during normal operation without excessive wear or other harmful effects.

The servo motor drives the mechanism to make the test samples repeat insertion and withdrawal actions. An external load can be used for the breaking capacity test. The power on / off time, test speed, stroke, and angle can all be preset on the touch screen.

Technical Parameters:

| Test Station | Single, can be customized |

| Electrical Control Method | PLC intelligent integrated control, with color humanized touch screen |

| Drive Mode | Servo motor drive |

| Sample Clamping Method | Mechanical clamping, the position of clamping point can be adjustable along the 3-axis fixture |

| Linear Stroke | 0-100mm, can be preset (the spacing between test plug and test socket≥ 50mm) |

| Conduction Time | 0-99.9s, can be preset (electrical contact should be maintained no more than 4s, no less than 2s) |

| Speed of Insertion and Separation | 0-0.85m/s can be preset, default (0.8±0.1) m/s |

| Test Cycles | 0~999999 cycles, can be preset (A stroke is an insertion or a withdrawal of a plug or vehicle connector with its mating accessory. A cycle is composed of two strokes, one for insertion and one for withdrawal.) |

| Test Frequency | 0-10 cycles/min, can be preset (3.75cycles/min=7.5 stoke/min) |

| Load Power | External, providing standard required voltage, current and power factor, recommended to work with the load cabinet SN224-300V80A |

| Test Contents |

Appliance coupler/charging interface breaking capacity test Appliance coupler / charging interface normal operating life test |

| Detection Function | An open circuit alarm can be realized during testing under load, and the cycles can be recorded real in time. |

| Safety Protection | Ground protection, short circuit protection |

| Power Supply | Single phase AC220V±10%, 50/60Hz, 10A |

|

Equipment Dimension & Weight |

L 1430mm * W 600mm * H1620mm, approx. 180KGS |

A vehicle connector and plug mechanical endurance test machine is a specialized testing equipment used to assess the durability and mechanical performance of vehicle connectors and plugs. These connectors and plugs are crucial components in vehicle electrical systems, providing the interface for electrical connections between various vehicle components. The mechanical endurance test machine simulates the repeated mating and unmating cycles that these connectors and plugs may undergo during vehicle operation. Here are the key features and components typically found in this test machine:

Test Fixture: The machine includes a test fixture designed to securely hold and position the vehicle connector and plug being tested. The fixture allows for controlled mating and unmating motions without damaging the connectors or plugs.

Actuation Mechanism: The test machine incorporates an actuation mechanism that applies repeated mating and unmating cycles to the connectors and plugs. This mechanism can be programmed to simulate specific mating forces, insertion and extraction speeds, and cycle patterns.

Force Measurement: The machine is equipped with force measurement sensors or load cells to measure the mating and unmating forces applied during the test. This allows for evaluating the force required for proper connection and disconnection of the connectors and plugs.

Displacement Measurement: The test machine includes displacement measurement devices, such as linear encoders or displacement transducers, to measure the relative movement or displacement of the connectors and plugs during the mating and unmating cycles.

Cycle Counter and Timer: The machine is equipped with a cycle counter and timer to track the number of mating and unmating cycles completed and measure the duration of the test. This information helps evaluate the endurance and mechanical performance of the connectors and plugs over time.

Control System: The test machine incorporates a control system that allows users to set the desired test parameters, such as force levels, cycle patterns, and speed. The control system also ensures accurate and repeatable testing procedures.

Data Acquisition and Analysis: The test machine may have data acquisition capabilities to record and analyze the test results. This includes monitoring factors such as mating and unmating forces, displacements, and any signs of wear or failure observed during the test.

Safety Features: Safety considerations are implemented in the machine to protect operators and ensure safe testing procedures. These features may include emergency stop buttons, protective enclosures, and safety interlocks.

The vehicle connector and plug mechanical endurance test machine is crucial for manufacturers and quality control departments to ensure the reliability and durability of connectors and plugs in vehicle electrical systems. By subjecting the connectors and plugs to repeated mating and unmating cycles, this machine helps identify any weaknesses, wear, or damage that may occur over time. The test results enable manufacturers to improve the design and materials of the connectors and plugs, ensuring their long-term performance and reliability in vehicle applications.