| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 5 Sets Per Month |

IEC60068-2 Temperature And Humidity Test Chamber 627L With Extremely Wide Control Range

Product overview:

This test chamber is used for cold, heat, humidity and dryness testing of raw materials and devices such as electronics, electricians, electrical appliances, plastics, etc. The purpose is to confirm the products reliability of storage and transportation under high and low temperature alternating heat and humidity, an necessary test equipment which is required by many standards such as IEC60335-1 clause 15, etc.

It conforms to standards:

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT”

IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT”

IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT”

IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle), IDT”

A temperature and humidity chamber, also known as a climate chamber or environmental chamber, is a specialized piece of equipment used to simulate and control temperature and humidity conditions for testing and evaluating the performance, reliability, and durability of various products and materials. It provides a controlled environment to subject test specimens to specific temperature and humidity levels, allowing for accelerated aging, performance testing, and research purposes. Here are the key features and functions typically found in a temperature and humidity chamber:

Temperature Control: The chamber is equipped with a temperature control system that can heat or cool the interior to achieve and maintain the desired temperature settings. The temperature range can vary depending on the specific model and can span from sub-zero temperatures to high temperatures, depending on the application requirements.

Humidity Control: The chamber incorporates a humidity control system that regulates the moisture content in the chamber's atmosphere. This system can provide precise control over relative humidity levels, allowing for testing under specific humidity conditions, such as high humidity or low humidity environments.

Programmable Settings: Temperature and humidity chambers often feature programmable settings, allowing users to define custom temperature and humidity profiles for their specific testing needs. These profiles can include ramp rates, dwell times, and cycling patterns to simulate real-world conditions or specific testing standards.

Uniformity and Stability: Temperature and humidity chambers are designed to provide uniform temperature and humidity distribution throughout the chamber's interior. The equipment ensures that the test specimens experience consistent conditions across the entire test area. Stability is critical to maintaining the desired temperature and humidity levels over extended periods.

Observation Windows and Lighting: The chamber may include observation windows made of tempered glass or other transparent materials. These windows enable users to visually inspect and monitor the test specimens without opening the chamber, ensuring the integrity of the controlled environment. Built-in lighting systems may also be present to enhance visibility inside the chamber.

Safety Features: Safety measures are an essential aspect of temperature and humidity chambers. These may include over-temperature protection, humidity sensor failure detection, power failure recovery, and audible or visual alarms to alert users of any abnormal conditions or equipment malfunctions.

Data Logging and Remote Control: Many modern temperature and humidity chambers offer data logging capabilities to record and store temperature and humidity data during testing. This data can be analyzed to assess product performance or compliance with standards. Some chambers also provide remote control and monitoring features, allowing users to access and control the chamber's settings from a computer or mobile device.

Temperature and humidity chambers are widely used in industries such as electronics, pharmaceuticals, automotive, aerospace, and materials science. They facilitate testing for product development, quality control, and research purposes, as well as providing insights into how materials and products behave under specific temperature and humidity conditions.

Structure:

This machine adopts a closed chamber structure with the following features:

A. It has an extremely wide temperature and humidity control range to meet the various needs of users.

B. It adopts a unique balanced temperature adjustment and humidity control mode to adjust the ideal temperature and humidity environment. The heating and humidification capability are stable and balanced, and the temperature and humidity control are high-precision and high-stability.

C. Automatic selection of refrigeration circuit: The automatic control device has the ability of automatically starting the running refrigeration circuit according to the set value of temperature, can start the cooling directly under the high temperature state.

The refrigeration adopts the air-cooled condensing unit with fully enclosed compressor (imported).

D. The door is equipped with an observation window, which is convenient for observing the test state of the test sample.

Technical parameters:

|

This test chamber prohibits: Testing or storage of flammable, explosive, and volatile substance samples Testing or storage of samples of corrosive substances Testing or storage of biological samples Testing or storage of strong electromagnetic emission source samples Testing or storage of radioactive material samples Test or storage of highly toxic substance samples Testing or storage of samples that may produce flammable, explosive, volatile, highly toxic, corrosive and radioactive materials during testing or storage |

|

|

|

672L |

|

W800mm×D600mm×H1400mm |

|

Approx. W1700mm×H1150mm×D1960mm |

|

Approx.650KG |

|

|

|

Temperature range: -20 ℃~+150℃ |

|

(20 ~ 98)% RH (refer to temperature and humidity controllable range chart, no active wet and heat load)

Temperature and humidity controllable range chart |

|

≤±0.5℃ (The temperature fluctuation is half of the difference between the measured maximum temperature and the minimum temperature at the center point) |

|

±2.0℃ (Temperature uniformity is the arithmetic mean of the difference between the highest and lowest temperature measured in each test) |

|

≥3℃/ min (non-linear under no load) |

|

≥1℃-1.2℃ /min (non-linear under no load) |

|

±3%RH |

|

Sound level≤85dB (Measured in a soundproof room with an ambient temperature of 25 ° C and low echo; using A weighting, the average value of 8 points is tested; each test point is 1 meter away from the noise source and 1 meter away from the ground) |

|

|

|

1. Outer wall material: Cold rolled steel plate, pickling and phosphating advanced powder baking paint 2.Inner wall material: SUS304# stainless steel plate 3. Chamber insulation material: rigid polyurethane foam + glass fiber |

|

Centrifugal fan; the air outlet can adjust the air volume, height and return air volume |

| 4.3. Door | Single open hinged door, equipped with observation window, lighting lamp, window/door frame anti-condensation electric heating device, door opening size: (approximately) 0.8*0.85M |

|

There is one conductive film explosion-proof tempered glass observation window on the door (with anti-condensation function) 300W×400H (mm) |

|

Long axis centrifugal fan |

|

Two built-in stainless steel adjustable movable tray racks, loading capacity 20KG/layer |

|

Use stainless steel impeller imported from Taiwan |

|

Nickel-chromium alloy electric heater |

|

French Tecumseh compressor |

|

Fin type evaporator |

|

Mechanical compressor cascade |

|

Air-cooling |

|

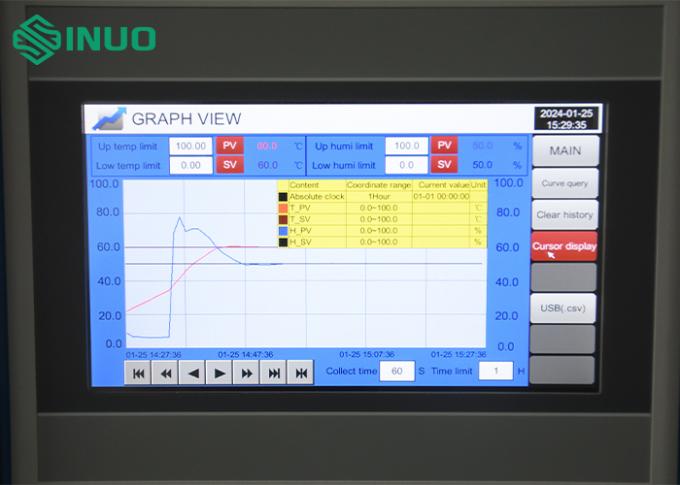

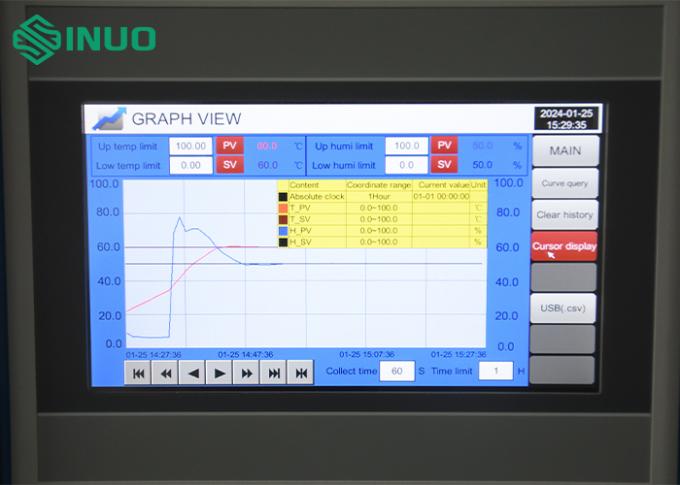

7-inch smart LCD touch programmable controller, brand: Weinview |

|

Φ50mm, 1pc, equipped with a special foam rubber plug (located on the left side of the chamber)

|

|

Equipped with a tri-color light on the top of the chamber for indicating the running status |

|

The top of the observation window is equipped with a light, controlled by the switch outside the door, for convenient and clear observation.

|

|

Yes |

|

|

| 5.1. Heating system | Stainless steel sleeve type anti-dry heating tube built-in nickel-chromium alloy heating wire |

| U-shaped fin type stainless steel high-speed heating electric heater is used for heating | |

| Completely independent system, does not affect the control circuit | |

|

Boiler heating and humidification method Stainless steel armored heater: Provides the heat required for water vaporization. Heater control mode: non-contact isocycle pulse width modulation, SSR (Solid State Relay) Equipped with water level control device and heater anti-drying device |

|

Cooling method: air-cooling |

| Refrigeration compressor: French Tecumseh compressor with environmentally friendly refrigerant | |

| Refrigerant copper tube: inner spiral K-TYPE refrigerant copper tube | |

| Condenser: wave-shaped fin type air-cooled condenser | |

| Evaporator: Slope type FIN—TUBE evaporator | |

| Freezing element: Original imported solenoid valve, drying filter, etc. | |

|

The pipelines of the whole system are subjected to a 22kg leak detection test |

| The heating and cooling system is completely independent | |

| The system can prevent high temperature and high pressure air flow back | |

| All refrigeration system action programs are completely controlled by the microcomputer controller | |

|

|

|

|

|

|

|

|

Forced circulation ventilation, balance temperature regulation method. The control system controls the output of the heater through the PID automatic calculation output according to the temperature point set by the system, and finally reaches a dynamic balance.

|

|

The built-in air-conditioning room, circulating air duct and long axial flow fan can improve the air flow and heating capacity by improving the air flow, and greatly improve the temperature uniformity of the test chamber. |

|

|

|

7 inch Weinview smart LCD touch programmable controller |

|

0.01℃/ 0.1%RH |

|

Arbitrary setting of fixed conditions, program conditions, and setting of curing test name, serial number, etc. |

|

0—999H59min |

|

At the same time, 120 groups of programs with different conditions can be set. In any group of programs, it can be divided into 1200 segments, and part of the number of segments can be intercepted arbitrarily to execute the cycle, or to perform cycle work of any section or group. |

|

It has a power-off memory device, which can continue to execute the remaining programs when the power is restored, and can be used as a machine appointment to execute the startup and machine running time. |

|

The temperature rise and fall can be used for slope control, curve control, and have the function of self-correcting temperature and humidity reference points. It has the function of PID automatic calculation, which can reduce the convenience caused by manual setting. |

|

U disk interface, RS-232 interface, misoperation hardware lock (LOCK), computer communication software is provided |

|

Settings and all conditions are automatically locked by microcomputer |

|

If an error occurs during setting or operation, a warning signal will be provided |

|

The controller has a recording signal port output, which can be connected to a temperature and humidity recorder and can output recording curves |

|

Equipped with standard RS-232 communication interface, long transmission distance, can be connected to PC for control and recording. |

|

|

|

1. Compressor overheating protection 2. Compressor overcurrent protection 3. Compressor high and low pressure protection 4. Compressor oil pressure protection (optional for large semi-hermetic compressors) 5. Over-temperature protection for liquid supply temperature 6. Ultra-high pressure relief protection 7. Air-cooled: condensing fan overheated protection |

|

1. Adjustable over temperature protection 2. Limit over-temperature protection of air conditioning channels 3. Fan motor overheat protection |

|

1. Overload and short circuit protection 2. The refrigeration system failure alarm protection caused by multiple openings of the cabinet |

|

The following conditions are guaranteed by the user |

|

1. The ground is level and well ventilated A:≥40cm B:≥150cm C:≥100cm D: ≥60cm E:≥40com |

|

1. Temperature: 5 ℃ ~ 35 ℃ 2. Relative humidity: ≤85% 3. Air pressure: 86kPa ~ 106kPa |

| 10.3. Power supply conditions | Power supply requirements: 1. One five-core (three-phase four-wire + protective ground wire) cable (about 4 meters long) 2. Voltage range: Three phase AC 400V 3. Allowable frequency fluctuation range: (50 ± 0.5) Hz 4. The protective earth ground resistance is less than 4Ω 5. The user is required to configure the equipment with an air or power switch of the corresponding capacity at the installation site, and this switch must be independently used by the device |

| 10.4. Maximum current Maximum power consumption |

Imax≤32A Pmax≤8.5KW |

| 10.5. Others | Opening the door of the test chamber during the test will cause temperature and humidity fluctuations in the chamber; if the door is opened multiple times or is left open for a long time or the test sample emits moisture during the test, the refrigeration system heat exchanger may freeze and does not work. |

| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 5 Sets Per Month |

IEC60068-2 Temperature And Humidity Test Chamber 627L With Extremely Wide Control Range

Product overview:

This test chamber is used for cold, heat, humidity and dryness testing of raw materials and devices such as electronics, electricians, electrical appliances, plastics, etc. The purpose is to confirm the products reliability of storage and transportation under high and low temperature alternating heat and humidity, an necessary test equipment which is required by many standards such as IEC60335-1 clause 15, etc.

It conforms to standards:

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT”

IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT”

IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT”

IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle), IDT”

A temperature and humidity chamber, also known as a climate chamber or environmental chamber, is a specialized piece of equipment used to simulate and control temperature and humidity conditions for testing and evaluating the performance, reliability, and durability of various products and materials. It provides a controlled environment to subject test specimens to specific temperature and humidity levels, allowing for accelerated aging, performance testing, and research purposes. Here are the key features and functions typically found in a temperature and humidity chamber:

Temperature Control: The chamber is equipped with a temperature control system that can heat or cool the interior to achieve and maintain the desired temperature settings. The temperature range can vary depending on the specific model and can span from sub-zero temperatures to high temperatures, depending on the application requirements.

Humidity Control: The chamber incorporates a humidity control system that regulates the moisture content in the chamber's atmosphere. This system can provide precise control over relative humidity levels, allowing for testing under specific humidity conditions, such as high humidity or low humidity environments.

Programmable Settings: Temperature and humidity chambers often feature programmable settings, allowing users to define custom temperature and humidity profiles for their specific testing needs. These profiles can include ramp rates, dwell times, and cycling patterns to simulate real-world conditions or specific testing standards.

Uniformity and Stability: Temperature and humidity chambers are designed to provide uniform temperature and humidity distribution throughout the chamber's interior. The equipment ensures that the test specimens experience consistent conditions across the entire test area. Stability is critical to maintaining the desired temperature and humidity levels over extended periods.

Observation Windows and Lighting: The chamber may include observation windows made of tempered glass or other transparent materials. These windows enable users to visually inspect and monitor the test specimens without opening the chamber, ensuring the integrity of the controlled environment. Built-in lighting systems may also be present to enhance visibility inside the chamber.

Safety Features: Safety measures are an essential aspect of temperature and humidity chambers. These may include over-temperature protection, humidity sensor failure detection, power failure recovery, and audible or visual alarms to alert users of any abnormal conditions or equipment malfunctions.

Data Logging and Remote Control: Many modern temperature and humidity chambers offer data logging capabilities to record and store temperature and humidity data during testing. This data can be analyzed to assess product performance or compliance with standards. Some chambers also provide remote control and monitoring features, allowing users to access and control the chamber's settings from a computer or mobile device.

Temperature and humidity chambers are widely used in industries such as electronics, pharmaceuticals, automotive, aerospace, and materials science. They facilitate testing for product development, quality control, and research purposes, as well as providing insights into how materials and products behave under specific temperature and humidity conditions.

Structure:

This machine adopts a closed chamber structure with the following features:

A. It has an extremely wide temperature and humidity control range to meet the various needs of users.

B. It adopts a unique balanced temperature adjustment and humidity control mode to adjust the ideal temperature and humidity environment. The heating and humidification capability are stable and balanced, and the temperature and humidity control are high-precision and high-stability.

C. Automatic selection of refrigeration circuit: The automatic control device has the ability of automatically starting the running refrigeration circuit according to the set value of temperature, can start the cooling directly under the high temperature state.

The refrigeration adopts the air-cooled condensing unit with fully enclosed compressor (imported).

D. The door is equipped with an observation window, which is convenient for observing the test state of the test sample.

Technical parameters:

|

This test chamber prohibits: Testing or storage of flammable, explosive, and volatile substance samples Testing or storage of samples of corrosive substances Testing or storage of biological samples Testing or storage of strong electromagnetic emission source samples Testing or storage of radioactive material samples Test or storage of highly toxic substance samples Testing or storage of samples that may produce flammable, explosive, volatile, highly toxic, corrosive and radioactive materials during testing or storage |

|

|

|

672L |

|

W800mm×D600mm×H1400mm |

|

Approx. W1700mm×H1150mm×D1960mm |

|

Approx.650KG |

|

|

|

Temperature range: -20 ℃~+150℃ |

|

(20 ~ 98)% RH (refer to temperature and humidity controllable range chart, no active wet and heat load)

Temperature and humidity controllable range chart |

|

≤±0.5℃ (The temperature fluctuation is half of the difference between the measured maximum temperature and the minimum temperature at the center point) |

|

±2.0℃ (Temperature uniformity is the arithmetic mean of the difference between the highest and lowest temperature measured in each test) |

|

≥3℃/ min (non-linear under no load) |

|

≥1℃-1.2℃ /min (non-linear under no load) |

|

±3%RH |

|

Sound level≤85dB (Measured in a soundproof room with an ambient temperature of 25 ° C and low echo; using A weighting, the average value of 8 points is tested; each test point is 1 meter away from the noise source and 1 meter away from the ground) |

|

|

|

1. Outer wall material: Cold rolled steel plate, pickling and phosphating advanced powder baking paint 2.Inner wall material: SUS304# stainless steel plate 3. Chamber insulation material: rigid polyurethane foam + glass fiber |

|

Centrifugal fan; the air outlet can adjust the air volume, height and return air volume |

| 4.3. Door | Single open hinged door, equipped with observation window, lighting lamp, window/door frame anti-condensation electric heating device, door opening size: (approximately) 0.8*0.85M |

|

There is one conductive film explosion-proof tempered glass observation window on the door (with anti-condensation function) 300W×400H (mm) |

|

Long axis centrifugal fan |

|

Two built-in stainless steel adjustable movable tray racks, loading capacity 20KG/layer |

|

Use stainless steel impeller imported from Taiwan |

|

Nickel-chromium alloy electric heater |

|

French Tecumseh compressor |

|

Fin type evaporator |

|

Mechanical compressor cascade |

|

Air-cooling |

|

7-inch smart LCD touch programmable controller, brand: Weinview |

|

Φ50mm, 1pc, equipped with a special foam rubber plug (located on the left side of the chamber)

|

|

Equipped with a tri-color light on the top of the chamber for indicating the running status |

|

The top of the observation window is equipped with a light, controlled by the switch outside the door, for convenient and clear observation.

|

|

Yes |

|

|

| 5.1. Heating system | Stainless steel sleeve type anti-dry heating tube built-in nickel-chromium alloy heating wire |

| U-shaped fin type stainless steel high-speed heating electric heater is used for heating | |

| Completely independent system, does not affect the control circuit | |

|

Boiler heating and humidification method Stainless steel armored heater: Provides the heat required for water vaporization. Heater control mode: non-contact isocycle pulse width modulation, SSR (Solid State Relay) Equipped with water level control device and heater anti-drying device |

|

Cooling method: air-cooling |

| Refrigeration compressor: French Tecumseh compressor with environmentally friendly refrigerant | |

| Refrigerant copper tube: inner spiral K-TYPE refrigerant copper tube | |

| Condenser: wave-shaped fin type air-cooled condenser | |

| Evaporator: Slope type FIN—TUBE evaporator | |

| Freezing element: Original imported solenoid valve, drying filter, etc. | |

|

The pipelines of the whole system are subjected to a 22kg leak detection test |

| The heating and cooling system is completely independent | |

| The system can prevent high temperature and high pressure air flow back | |

| All refrigeration system action programs are completely controlled by the microcomputer controller | |

|

|

|

|

|

|

|

|

Forced circulation ventilation, balance temperature regulation method. The control system controls the output of the heater through the PID automatic calculation output according to the temperature point set by the system, and finally reaches a dynamic balance.

|

|

The built-in air-conditioning room, circulating air duct and long axial flow fan can improve the air flow and heating capacity by improving the air flow, and greatly improve the temperature uniformity of the test chamber. |

|

|

|

7 inch Weinview smart LCD touch programmable controller |

|

0.01℃/ 0.1%RH |

|

Arbitrary setting of fixed conditions, program conditions, and setting of curing test name, serial number, etc. |

|

0—999H59min |

|

At the same time, 120 groups of programs with different conditions can be set. In any group of programs, it can be divided into 1200 segments, and part of the number of segments can be intercepted arbitrarily to execute the cycle, or to perform cycle work of any section or group. |

|

It has a power-off memory device, which can continue to execute the remaining programs when the power is restored, and can be used as a machine appointment to execute the startup and machine running time. |

|

The temperature rise and fall can be used for slope control, curve control, and have the function of self-correcting temperature and humidity reference points. It has the function of PID automatic calculation, which can reduce the convenience caused by manual setting. |

|

U disk interface, RS-232 interface, misoperation hardware lock (LOCK), computer communication software is provided |

|

Settings and all conditions are automatically locked by microcomputer |

|

If an error occurs during setting or operation, a warning signal will be provided |

|

The controller has a recording signal port output, which can be connected to a temperature and humidity recorder and can output recording curves |

|

Equipped with standard RS-232 communication interface, long transmission distance, can be connected to PC for control and recording. |

|

|

|

1. Compressor overheating protection 2. Compressor overcurrent protection 3. Compressor high and low pressure protection 4. Compressor oil pressure protection (optional for large semi-hermetic compressors) 5. Over-temperature protection for liquid supply temperature 6. Ultra-high pressure relief protection 7. Air-cooled: condensing fan overheated protection |

|

1. Adjustable over temperature protection 2. Limit over-temperature protection of air conditioning channels 3. Fan motor overheat protection |

|

1. Overload and short circuit protection 2. The refrigeration system failure alarm protection caused by multiple openings of the cabinet |

|

The following conditions are guaranteed by the user |

|

1. The ground is level and well ventilated A:≥40cm B:≥150cm C:≥100cm D: ≥60cm E:≥40com |

|

1. Temperature: 5 ℃ ~ 35 ℃ 2. Relative humidity: ≤85% 3. Air pressure: 86kPa ~ 106kPa |

| 10.3. Power supply conditions | Power supply requirements: 1. One five-core (three-phase four-wire + protective ground wire) cable (about 4 meters long) 2. Voltage range: Three phase AC 400V 3. Allowable frequency fluctuation range: (50 ± 0.5) Hz 4. The protective earth ground resistance is less than 4Ω 5. The user is required to configure the equipment with an air or power switch of the corresponding capacity at the installation site, and this switch must be independently used by the device |

| 10.4. Maximum current Maximum power consumption |

Imax≤32A Pmax≤8.5KW |

| 10.5. Others | Opening the door of the test chamber during the test will cause temperature and humidity fluctuations in the chamber; if the door is opened multiple times or is left open for a long time or the test sample emits moisture during the test, the refrigeration system heat exchanger may freeze and does not work. |