| MOQ: | 1 Set |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 10 Sets / Month |

IEC 62196-1: 2022 EV Switch-Outletor Apparatus For Checking The Withdrawal Force

Product InformationN For Apparatus For Checking The Withdrawal Force:

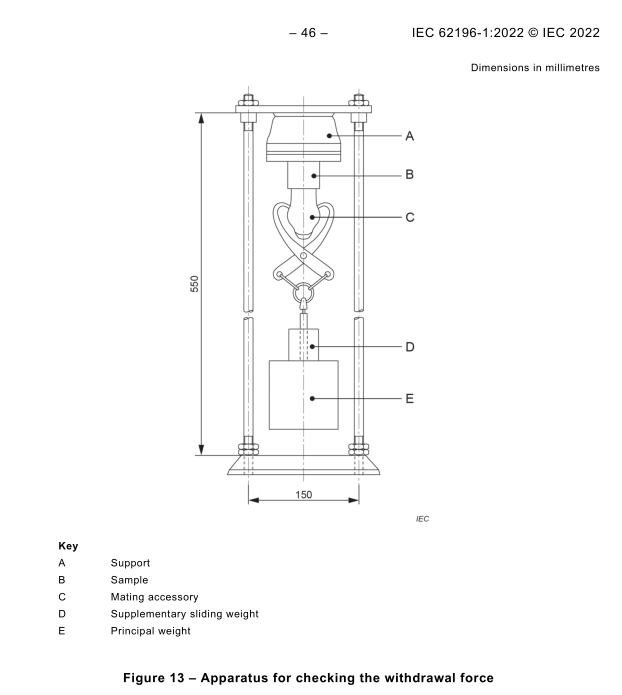

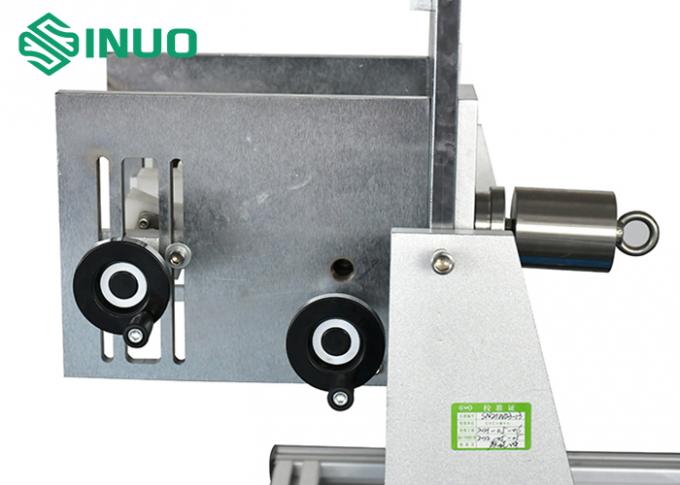

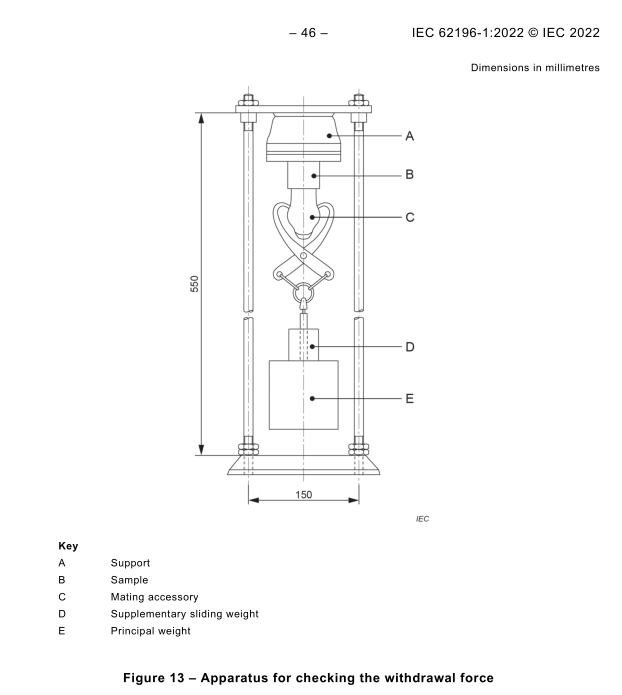

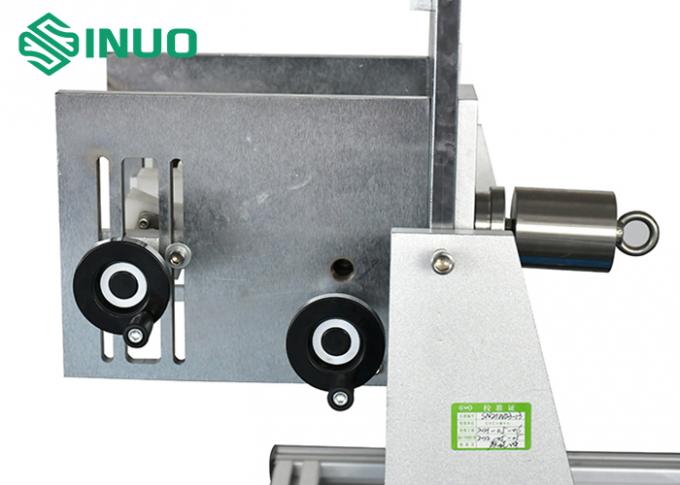

This test equipment conforms to IEC 62196-1:2022 clause 14.1.5, 14.1.6, figure 13, figure 14. It is used to check the maximum force required when the test plug is withdrawn from the socket-outlet or vehicle connector. It is also used to verify the design of latching device holding the plug in the socket-outlet or vehicle connector shall remain in latched position during use.

Maximum Withdrawal Force Test For Apparatus For Checking The Withdrawal Force:

The maximum withdrawal force of the socket-outlet shall meet the requirements of Table 1.

Apply the maximum withdrawal force specified in the standard (total force of the principal weight, supplementary weight, hook (clamping device) to the test plug, when the supplementary weight is dropped from a height of 50mm, the plug should come out of the socket.

User should select an appropriate weight for the test according to the following table:

Table 1

|

Sample type (AC A) |

Withdrawal N |

Principal weight N |

Supplementary weight N |

| 6-40 | 165 | 148.5 | 16.5 |

| 41-80 | 300 | 270 | 30 |

| 81-150 | 440 | 396 | 44 |

| 151-250 | 660 | 396+148.5+49.5 | 66 |

|

Sample type (DC A) |

|||

| Any | 750 | 396+148.5+49.5+15 | 75 |

| Clause 17.2 A | |||

| <59 | 150 | 135 | 15 |

| 60-99 | 275 | 247.5 | 27.5 |

| 100-125 | 400 | 270+90 | 40 |

| Note: The principal weight already contains the test plug and hook weight | |||

Minimum Withdrawal Force For Apparatus For Checking The Withdrawal Force:

Insert the gauge with the minimum withdrawal force specified in the standard (that is, the test pin (single pin) that meets the requirements of this standard, the total mass of the pin should be equal to the value specified in the table) into each individual socket in the socket-outlet. The gauge must not be removed from the socket within 30 seconds.

Table 2

|

Nominal pin diameter mm |

Diameter of gauge mm +0 -0.01 |

Minimum total force N |

| 5 | 4.80 | 2.5 |

| 6 | 5.80 | 5 |

| 7 | 6.80 | 5 |

| 8 | 7.80 | 10 |

| 10 | 9.80 | 15 |

| 12 | 11.80 | 20 |

| Note: The minimum withdrawal force already includes the weight of the gauge | ||

Test Method For Apparatus For Checking The Withdrawal Force:

The switched EV socket-outlet or switched vehicle connector with interlock is fixed to the support of an apparatus as shown in Figure 13 so that the axis of separation is vertical, and the movement of the mating accessory is downwards. With the latching devices holding the Ev plug into the EV socket-outlet, or vehicle connector into the vehicle inlet, in the engaged position, an axial pull is applied to an appropriate EV plug inserted in the switched EV socket-outlet, or vehicle connector inserted into the vehicle inlet, with interlock. The test EV plug orvehicle inlet, in accordance with the relevant standard sheets, shall have finely ground contacts of hardened steel, having a surface roughness not exceeding 0.8 pm over their active lengthand spaced at the nominal distances, with a tolerance of ±0.05 mm.

The EV plug contacts are wiped free from grease before the test.

The test EV plug, or vehicle connector, is inserted into and withdrawn from the EV socket-outletor vehicle inlet, ten times. lt is then inserted again with a mass being attached to it by means of a suitable clamp. The total mass of the mating accessory, the clamp, the carrier, the principal and the supplementary weight shall exert a force according to Table 5 upon the connection point. The supplementary weight shall be such that it exerts a force equal to one-tenth of the withdrawal force. The retaining means, if any, shall be opened.

The principal weight is hung without jolting on the test mating accessory, and the supplementary weight is allowed to fall from a height of 5 cm onto the principal weight.

After this test, the total weight shall be maintained for 60 s.

| MOQ: | 1 Set |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 10 Sets / Month |

IEC 62196-1: 2022 EV Switch-Outletor Apparatus For Checking The Withdrawal Force

Product InformationN For Apparatus For Checking The Withdrawal Force:

This test equipment conforms to IEC 62196-1:2022 clause 14.1.5, 14.1.6, figure 13, figure 14. It is used to check the maximum force required when the test plug is withdrawn from the socket-outlet or vehicle connector. It is also used to verify the design of latching device holding the plug in the socket-outlet or vehicle connector shall remain in latched position during use.

Maximum Withdrawal Force Test For Apparatus For Checking The Withdrawal Force:

The maximum withdrawal force of the socket-outlet shall meet the requirements of Table 1.

Apply the maximum withdrawal force specified in the standard (total force of the principal weight, supplementary weight, hook (clamping device) to the test plug, when the supplementary weight is dropped from a height of 50mm, the plug should come out of the socket.

User should select an appropriate weight for the test according to the following table:

Table 1

|

Sample type (AC A) |

Withdrawal N |

Principal weight N |

Supplementary weight N |

| 6-40 | 165 | 148.5 | 16.5 |

| 41-80 | 300 | 270 | 30 |

| 81-150 | 440 | 396 | 44 |

| 151-250 | 660 | 396+148.5+49.5 | 66 |

|

Sample type (DC A) |

|||

| Any | 750 | 396+148.5+49.5+15 | 75 |

| Clause 17.2 A | |||

| <59 | 150 | 135 | 15 |

| 60-99 | 275 | 247.5 | 27.5 |

| 100-125 | 400 | 270+90 | 40 |

| Note: The principal weight already contains the test plug and hook weight | |||

Minimum Withdrawal Force For Apparatus For Checking The Withdrawal Force:

Insert the gauge with the minimum withdrawal force specified in the standard (that is, the test pin (single pin) that meets the requirements of this standard, the total mass of the pin should be equal to the value specified in the table) into each individual socket in the socket-outlet. The gauge must not be removed from the socket within 30 seconds.

Table 2

|

Nominal pin diameter mm |

Diameter of gauge mm +0 -0.01 |

Minimum total force N |

| 5 | 4.80 | 2.5 |

| 6 | 5.80 | 5 |

| 7 | 6.80 | 5 |

| 8 | 7.80 | 10 |

| 10 | 9.80 | 15 |

| 12 | 11.80 | 20 |

| Note: The minimum withdrawal force already includes the weight of the gauge | ||

Test Method For Apparatus For Checking The Withdrawal Force:

The switched EV socket-outlet or switched vehicle connector with interlock is fixed to the support of an apparatus as shown in Figure 13 so that the axis of separation is vertical, and the movement of the mating accessory is downwards. With the latching devices holding the Ev plug into the EV socket-outlet, or vehicle connector into the vehicle inlet, in the engaged position, an axial pull is applied to an appropriate EV plug inserted in the switched EV socket-outlet, or vehicle connector inserted into the vehicle inlet, with interlock. The test EV plug orvehicle inlet, in accordance with the relevant standard sheets, shall have finely ground contacts of hardened steel, having a surface roughness not exceeding 0.8 pm over their active lengthand spaced at the nominal distances, with a tolerance of ±0.05 mm.

The EV plug contacts are wiped free from grease before the test.

The test EV plug, or vehicle connector, is inserted into and withdrawn from the EV socket-outletor vehicle inlet, ten times. lt is then inserted again with a mass being attached to it by means of a suitable clamp. The total mass of the mating accessory, the clamp, the carrier, the principal and the supplementary weight shall exert a force according to Table 5 upon the connection point. The supplementary weight shall be such that it exerts a force equal to one-tenth of the withdrawal force. The retaining means, if any, shall be opened.

The principal weight is hung without jolting on the test mating accessory, and the supplementary weight is allowed to fall from a height of 5 cm onto the principal weight.

After this test, the total weight shall be maintained for 60 s.