| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 30 Sets Per Month |

UL154B Water Spray Test Apparatus With 3 UL Spray Heads Manual Version

Product Information:

The testing equipment is used to verify the protective performance of the enclosure for self-ballasted lamps and lamp adapters under UL water spray environment.

The water ingress testing equipment apply spray test to test sample by controlling the water supply pressure and the distance between the nozzle and sample.

Standards Compliant:

UL1993 “Self-Ballasted Lamps and Lamp Adapters” clause 24, figure 24.1 and 24.2

UL60507-ENGL 1999 figure 38.1 and 38.2

ANSI Z21.10.3-2004

ANSI Z21.58 Figure 10/Figure 11

CSA4.3-2004

UL1598, UL153, UL154B, UL1703, UL8750, UL1741, UL514B, UL1278, UL1571, etc.

Features:

A water spray test apparatus, also known as a water spray test chamber or water spray nozzle system, is a specialized equipment used to assess the resistance of electronic devices, enclosures, or materials to water spray or jetting. This type of testing is often conducted to evaluate the ingress protection (IP) rating of the test specimen according to standards like the International Electrotechnical Commission (IEC) 60529 or the National Electrical Manufacturers Association (NEMA) standards. Here are the key features and functions typically associated with a water spray test apparatus:

Test Chamber: The apparatus consists of a testing chamber or enclosure where the test specimen is placed. The chamber is designed to contain the water spray or jetting and prevent water from escaping outside the testing area.

Water Supply System: The apparatus incorporates a water supply system that provides a controlled and pressurized water source. This system typically includes pumps, valves, and filters to maintain a consistent and specified water pressure and flow rate during the test.

Spray Nozzles: The apparatus features spray nozzles or jets strategically positioned within the test chamber. These nozzles generate a directed water spray or jetting pattern onto the test specimen. The number, size, and arrangement of the nozzles may vary depending on the specific testing requirements and standards being followed.

Water Pressure and Flow Control: The apparatus allows precise control over the water pressure and flow rate during the test. This control ensures that the water spray or jetting meets the required specifications outlined in the testing standards.

Angle Adjustment: Some water spray test apparatuses offer the ability to adjust the angle of the spray nozzles. This feature allows for testing at different angles to simulate real-world scenarios where the test specimen may be exposed to water from various directions.

Test Duration Control: The apparatus provides control over the duration of the water spray or jetting test. The test duration is typically specified in the relevant standards, and the apparatus allows for precise timing and automation of the test process.

Compliance with Standards: A water spray test apparatus is designed to comply with specific industry standards such as IEC 60529 or NEMA standards. Compliance ensures that the testing process is conducted according to established guidelines and provides reliable and comparable results.

Water spray test apparatuses are commonly used in industries such as automotive, aerospace, electronics, and outdoor equipment manufacturing. They enable manufacturers to evaluate the waterproof or water-resistant properties of their products, ensuring they meet the required IP ratings and can withstand exposure to water spray or jetting without compromising functionality or safety.

Technical Parameters:

| Control & Operation | Manual |

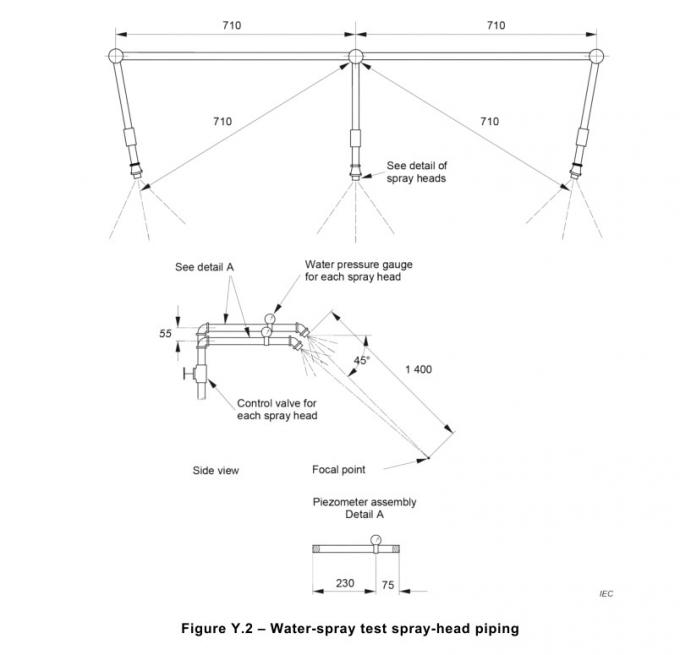

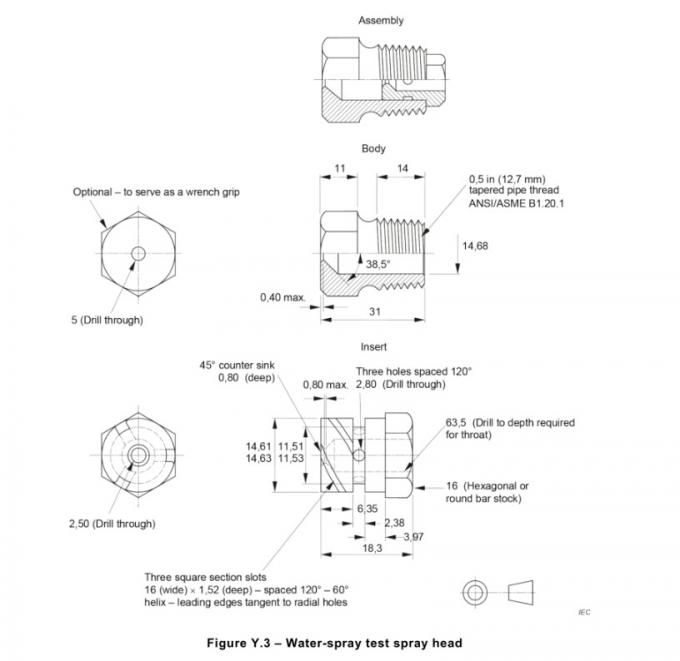

| Spray Heads | 3 pieces (or 4 pieces optional, with one lower nozzle), manufactured according to UL1993figure 24.1 |

| Spray Heads Positions | The positions of spray heads can be adjusted up or down through the water spray pipe rack, the spacing is made according to UL1993 Figure 24.2 |

| Lower Nozzle Angle (Optional) | 45° up |

| Water Pressure | At each head at approximately 34.5Kpa (5 psi), each spray head has a corresponding press gauge, total water flow pressure is 50-150Kpa |

| Distance between the center Nozzle and the Device | Approximately 1.4m (55 inches) |

| Rack | Material: high-grade aluminum profile with casters |

The device consists of a 3 UL spray heads, 3 pressure gauges, 3 control valves and a water supply pipe rack.

Note: we only quote the test apparatus, the water supply should be offered by client.

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 30 Sets Per Month |

UL154B Water Spray Test Apparatus With 3 UL Spray Heads Manual Version

Product Information:

The testing equipment is used to verify the protective performance of the enclosure for self-ballasted lamps and lamp adapters under UL water spray environment.

The water ingress testing equipment apply spray test to test sample by controlling the water supply pressure and the distance between the nozzle and sample.

Standards Compliant:

UL1993 “Self-Ballasted Lamps and Lamp Adapters” clause 24, figure 24.1 and 24.2

UL60507-ENGL 1999 figure 38.1 and 38.2

ANSI Z21.10.3-2004

ANSI Z21.58 Figure 10/Figure 11

CSA4.3-2004

UL1598, UL153, UL154B, UL1703, UL8750, UL1741, UL514B, UL1278, UL1571, etc.

Features:

A water spray test apparatus, also known as a water spray test chamber or water spray nozzle system, is a specialized equipment used to assess the resistance of electronic devices, enclosures, or materials to water spray or jetting. This type of testing is often conducted to evaluate the ingress protection (IP) rating of the test specimen according to standards like the International Electrotechnical Commission (IEC) 60529 or the National Electrical Manufacturers Association (NEMA) standards. Here are the key features and functions typically associated with a water spray test apparatus:

Test Chamber: The apparatus consists of a testing chamber or enclosure where the test specimen is placed. The chamber is designed to contain the water spray or jetting and prevent water from escaping outside the testing area.

Water Supply System: The apparatus incorporates a water supply system that provides a controlled and pressurized water source. This system typically includes pumps, valves, and filters to maintain a consistent and specified water pressure and flow rate during the test.

Spray Nozzles: The apparatus features spray nozzles or jets strategically positioned within the test chamber. These nozzles generate a directed water spray or jetting pattern onto the test specimen. The number, size, and arrangement of the nozzles may vary depending on the specific testing requirements and standards being followed.

Water Pressure and Flow Control: The apparatus allows precise control over the water pressure and flow rate during the test. This control ensures that the water spray or jetting meets the required specifications outlined in the testing standards.

Angle Adjustment: Some water spray test apparatuses offer the ability to adjust the angle of the spray nozzles. This feature allows for testing at different angles to simulate real-world scenarios where the test specimen may be exposed to water from various directions.

Test Duration Control: The apparatus provides control over the duration of the water spray or jetting test. The test duration is typically specified in the relevant standards, and the apparatus allows for precise timing and automation of the test process.

Compliance with Standards: A water spray test apparatus is designed to comply with specific industry standards such as IEC 60529 or NEMA standards. Compliance ensures that the testing process is conducted according to established guidelines and provides reliable and comparable results.

Water spray test apparatuses are commonly used in industries such as automotive, aerospace, electronics, and outdoor equipment manufacturing. They enable manufacturers to evaluate the waterproof or water-resistant properties of their products, ensuring they meet the required IP ratings and can withstand exposure to water spray or jetting without compromising functionality or safety.

Technical Parameters:

| Control & Operation | Manual |

| Spray Heads | 3 pieces (or 4 pieces optional, with one lower nozzle), manufactured according to UL1993figure 24.1 |

| Spray Heads Positions | The positions of spray heads can be adjusted up or down through the water spray pipe rack, the spacing is made according to UL1993 Figure 24.2 |

| Lower Nozzle Angle (Optional) | 45° up |

| Water Pressure | At each head at approximately 34.5Kpa (5 psi), each spray head has a corresponding press gauge, total water flow pressure is 50-150Kpa |

| Distance between the center Nozzle and the Device | Approximately 1.4m (55 inches) |

| Rack | Material: high-grade aluminum profile with casters |

The device consists of a 3 UL spray heads, 3 pressure gauges, 3 control valves and a water supply pipe rack.

Note: we only quote the test apparatus, the water supply should be offered by client.