| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 1 Month |

| Payment Method: | T/T |

| Supply Capacity: | 15 Sets per Month |

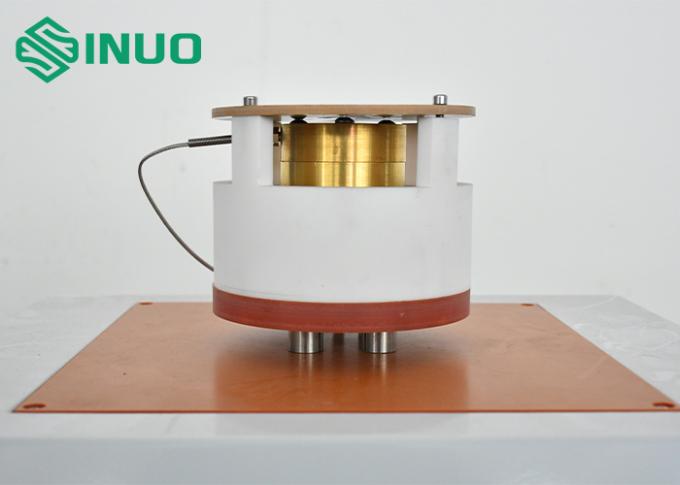

VDE 0620-1-2005 Abnormal Heat Of Insulating Sleeves Of Plug Pins Testing Apparatus

Product information:

This device meets the standards of IEC60884-1 clause28.1.2 figure 40. It is applicable to test improper heating resistance and burning resistance of plug pins and plug with insulation sleeve. Use a heating plate to heat the copper socket to simulate the abnormal heat of the plug and pin insulation sleeve, so as to test its heat resistance performance. It can imitate the insulated parts of which the plug-and-socket device’s safety performance may be damaged by electric heat stress. It should not be over damaged for exposure to overheating and under fire. This device is equipped with imported high-precision digital indicator, high quality thermocouple, and high-performance heating device, stable performance.

An apparatus for testing the abnormal heat of insulating sleeves of plug pins is designed to evaluate the thermal performance and resistance of insulating sleeves used in electrical plug pins when exposed to excessive heat or abnormal operating conditions. This test is crucial for ensuring the safety and reliability of electrical connections. Here are the key features and components typically found in such an apparatus:

Test Fixture: The apparatus includes a specialized test fixture that securely holds the plug pins and allows for the controlled application of heat to the insulating sleeves. The fixture ensures proper positioning and alignment of the plug pins during the test.

Heating Element: The apparatus incorporates a heating element or heat source that provides the means to apply controlled heat to the insulating sleeves. This can be achieved through electric heating coils, infrared heaters, or other suitable heating methods.

Temperature Measurement: Temperature measurement devices, such as thermocouples or infrared sensors, are used to monitor and record the temperature at specific points on the insulating sleeves. These devices allow for accurate assessment of the thermal performance and response of the sleeves to abnormal heat conditions.

Control System: The apparatus is equipped with a control system that allows users to set and adjust various parameters, such as the temperature, heating duration, and ramp-up rate. The control system ensures precise control over the heating process and facilitates the safe operation of the apparatus.

Thermal Protection: To prevent overheating and ensure operator safety, the apparatus may incorporate thermal protection mechanisms. These mechanisms can include temperature limit switches, safety interlocks, and emergency shut-off systems to prevent excessive heat buildup and potential hazards.

Data Acquisition and Analysis: The apparatus may have data acquisition and analysis capabilities to record and analyze the test results. This can include monitoring and logging temperature profiles, evaluating heat dissipation characteristics, and assessing any signs of insulation failure or degradation.

Safety Features: Safety considerations are paramount in the design of the apparatus to protect operators and prevent accidents. This may include safety enclosures, protective shields, and safety protocols to ensure safe handling of the test samples and minimize risks associated with abnormal heat conditions.

The apparatus for testing abnormal heat of insulating sleeves of plug pins is essential for quality control departments, manufacturers, and regulatory bodies to evaluate the thermal performance and safety of electrical connections. By subjecting the insulating sleeves to controlled heat conditions, this test helps identify potential issues, such as insulation breakdown, melting, or deformation, and ensures compliance with safety standards and regulations. The test results aid in the improvement of insulating materials and designs, enhancing the overall reliability and safety of electrical plug pins.

Technical parameters:

| Dimension | 400×400×450(mm) |

| Insulation board(mm) | Thickness 5 |

| Metal material | Brass |

| Power supply | AC220V±10%/50-60Hz |

| Temperature | 0-40℃ |

| Humidity | 30%-90% |

| Constant temperature time | 0-9999 hours,can be preset |

| Weight | 30kg |

| Heating temperature | Normal temperature 200°C±5°C |

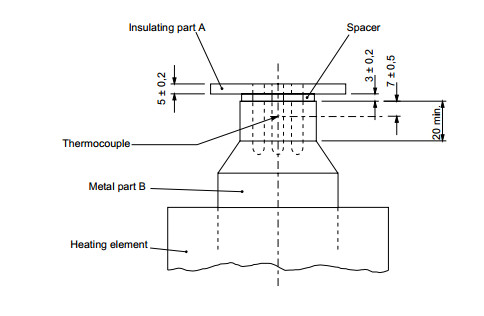

1. Insulating plate A: 5 mm thickness round flat surface, the diameter of the two times as test product surface' diameter.

2. The metal part B (Fixture): the length is more than 20 mm, brass, five pieces, can be replaced; Gap between insulation board and metal parts B: 3 mm, ensuring surrounding cross-ventilation;

3. Distance between thermocouple and the metal parts B: 7 mm;

4. Bolt hole of Metal parts B: more than 0.1 mm;

5. Equipped with K-type electric heater, imported high-precision digital-display table.

6. Power supply: 220V AC, 50Hz

Come with a BS1363 13A socket-outlet gauge.

| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 1 Month |

| Payment Method: | T/T |

| Supply Capacity: | 15 Sets per Month |

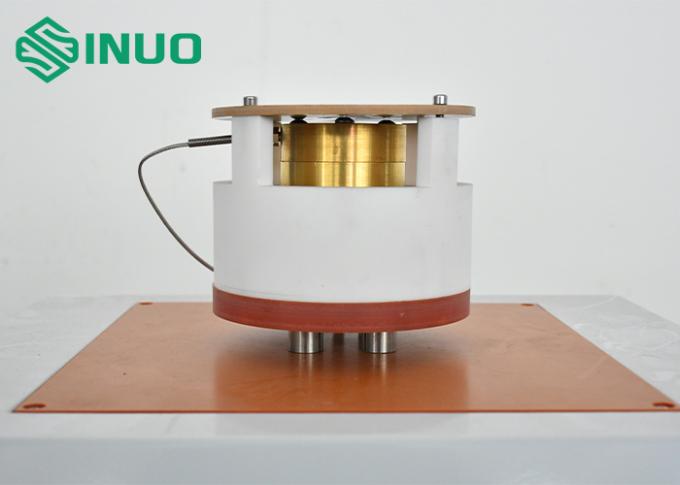

VDE 0620-1-2005 Abnormal Heat Of Insulating Sleeves Of Plug Pins Testing Apparatus

Product information:

This device meets the standards of IEC60884-1 clause28.1.2 figure 40. It is applicable to test improper heating resistance and burning resistance of plug pins and plug with insulation sleeve. Use a heating plate to heat the copper socket to simulate the abnormal heat of the plug and pin insulation sleeve, so as to test its heat resistance performance. It can imitate the insulated parts of which the plug-and-socket device’s safety performance may be damaged by electric heat stress. It should not be over damaged for exposure to overheating and under fire. This device is equipped with imported high-precision digital indicator, high quality thermocouple, and high-performance heating device, stable performance.

An apparatus for testing the abnormal heat of insulating sleeves of plug pins is designed to evaluate the thermal performance and resistance of insulating sleeves used in electrical plug pins when exposed to excessive heat or abnormal operating conditions. This test is crucial for ensuring the safety and reliability of electrical connections. Here are the key features and components typically found in such an apparatus:

Test Fixture: The apparatus includes a specialized test fixture that securely holds the plug pins and allows for the controlled application of heat to the insulating sleeves. The fixture ensures proper positioning and alignment of the plug pins during the test.

Heating Element: The apparatus incorporates a heating element or heat source that provides the means to apply controlled heat to the insulating sleeves. This can be achieved through electric heating coils, infrared heaters, or other suitable heating methods.

Temperature Measurement: Temperature measurement devices, such as thermocouples or infrared sensors, are used to monitor and record the temperature at specific points on the insulating sleeves. These devices allow for accurate assessment of the thermal performance and response of the sleeves to abnormal heat conditions.

Control System: The apparatus is equipped with a control system that allows users to set and adjust various parameters, such as the temperature, heating duration, and ramp-up rate. The control system ensures precise control over the heating process and facilitates the safe operation of the apparatus.

Thermal Protection: To prevent overheating and ensure operator safety, the apparatus may incorporate thermal protection mechanisms. These mechanisms can include temperature limit switches, safety interlocks, and emergency shut-off systems to prevent excessive heat buildup and potential hazards.

Data Acquisition and Analysis: The apparatus may have data acquisition and analysis capabilities to record and analyze the test results. This can include monitoring and logging temperature profiles, evaluating heat dissipation characteristics, and assessing any signs of insulation failure or degradation.

Safety Features: Safety considerations are paramount in the design of the apparatus to protect operators and prevent accidents. This may include safety enclosures, protective shields, and safety protocols to ensure safe handling of the test samples and minimize risks associated with abnormal heat conditions.

The apparatus for testing abnormal heat of insulating sleeves of plug pins is essential for quality control departments, manufacturers, and regulatory bodies to evaluate the thermal performance and safety of electrical connections. By subjecting the insulating sleeves to controlled heat conditions, this test helps identify potential issues, such as insulation breakdown, melting, or deformation, and ensures compliance with safety standards and regulations. The test results aid in the improvement of insulating materials and designs, enhancing the overall reliability and safety of electrical plug pins.

Technical parameters:

| Dimension | 400×400×450(mm) |

| Insulation board(mm) | Thickness 5 |

| Metal material | Brass |

| Power supply | AC220V±10%/50-60Hz |

| Temperature | 0-40℃ |

| Humidity | 30%-90% |

| Constant temperature time | 0-9999 hours,can be preset |

| Weight | 30kg |

| Heating temperature | Normal temperature 200°C±5°C |

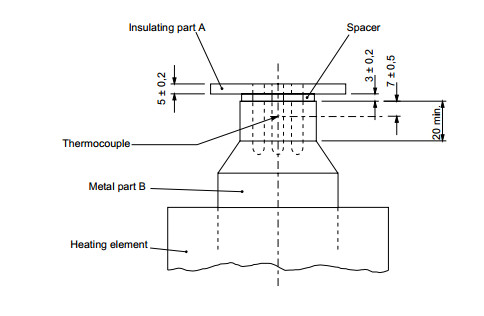

1. Insulating plate A: 5 mm thickness round flat surface, the diameter of the two times as test product surface' diameter.

2. The metal part B (Fixture): the length is more than 20 mm, brass, five pieces, can be replaced; Gap between insulation board and metal parts B: 3 mm, ensuring surrounding cross-ventilation;

3. Distance between thermocouple and the metal parts B: 7 mm;

4. Bolt hole of Metal parts B: more than 0.1 mm;

5. Equipped with K-type electric heater, imported high-precision digital-display table.

6. Power supply: 220V AC, 50Hz

Come with a BS1363 13A socket-outlet gauge.