|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 20 Sets Per Month |

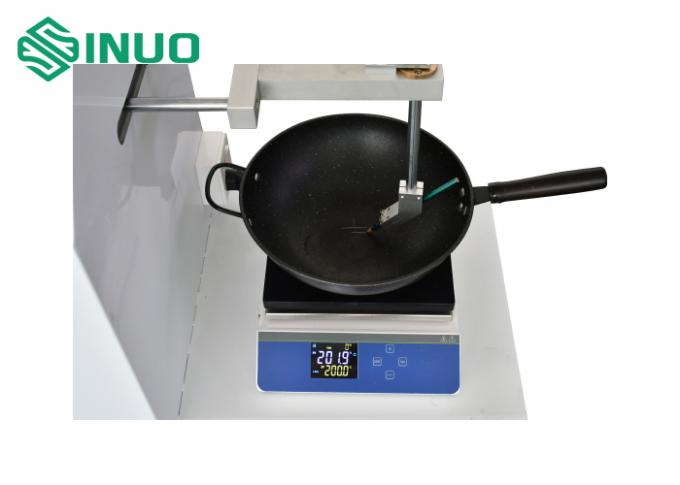

BS EN 12983-1 Pencil Hardness Test Apparatus For Exterior Organic Coatings Test Scratch Resistance

Product overview:

The equipment is complied with BS EN 12983-1 clause 8.4.2 ,8.4.3 and Appendix K. The device uses the pencil nib to compare the scratch resistance of the coating; Apply 4&8N pressure to the pencil, insert the pen core into the hole where the hole is 45° , then the pencil nib completely touches the bottom coating of the pot, and then draw a 2~5cm line on the coating; Judge the effect by the lines drawn.

The pencil hardness test apparatus for exterior organic coatings is a specialized device used to assess the hardness and scratch resistance of coatings applied to exterior surfaces, such as paints, varnishes, and protective coatings. The test determines the ability of the coating to resist the penetration and scratching of a pencil under controlled conditions. Here are the key features and components typically found in a pencil hardness test apparatus:

Test Panel Holder: The apparatus includes a test panel holder that securely holds the coated sample during the test. The holder ensures proper positioning and stability of the panel to ensure consistent and accurate results.

Pencil Holder: The pencil holder or clamp securely holds the pencil in place during the test. It ensures that the pencil is at a specified angle and is in contact with the coating surface during the test.

Test Procedure Guide: The apparatus may include a test procedure guide that provides instructions on how to conduct the pencil hardness test correctly. It outlines the specific testing parameters, such as the angle of the pencil, the applied force, and the number of passes over the coating surface.

Force Application Mechanism: The apparatus incorporates a mechanism to apply a controlled force on the pencil as it moves across the coating surface. This mechanism ensures consistent force application during the test, allowing for accurate comparisons between different coatings.

Result Evaluation: After conducting the test, the apparatus enables the evaluation of the test results. Typically, the test panel is visually inspected for any visible scratches or marks caused by the pencil. The hardness of the coating is determined based on the pencil grade that produces the first visible scratch.

Data Recording and Analysis: The apparatus may have data recording and analysis capabilities to document the test results. This can include recording the pencil grade used, the observed scratches, and any additional information relevant to the evaluation of the coating's hardness.

The pencil hardness test apparatus is widely used in the coatings industry to assess the scratch resistance and hardness of exterior organic coatings. By subjecting the coating to controlled pencil abrasion, this test helps manufacturers and quality control departments evaluate the performance and durability of coatings under real-world conditions. The test results aid in selecting appropriate coatings for exterior applications and ensuring their long-term protection and aesthetic appeal.

Technical parameters:

1. Power supply: AC220V, 50HZ

2. Test station: 1

3. Drive mode: electric + eccentric wheel mechanism

4. Test speed: 0-10 times/min, adjustable

5. Scratch length: 20~50mm, adjustable, default 25mm

6. Scratch angle:45 °

7. Heating platform DB-2EFS:RT+10°C~420°C±1°C, Platform size:L450*W350mm

8. Test mass: one of each 4N, 8N.

9. Pencil: one of each HB,2H,3H,4H,5H.

10. Overall dimension:WDH=900×500×700mm, Maximum allowable sample Ф400mm.

Main configuration list:

| No. | Content | Quantity | Unit |

| 1 | Scratch Resistance Tester | 1 | Set |

| 2 | Heating platform | 1 | Set |

| 3 | Test mass:4N, 8N | 1 | Set |

| 4 | Pencil | 1 | Set |

|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 20 Sets Per Month |

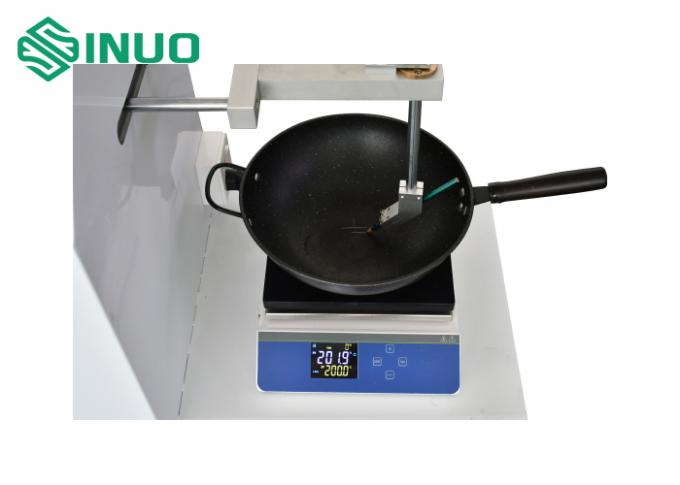

BS EN 12983-1 Pencil Hardness Test Apparatus For Exterior Organic Coatings Test Scratch Resistance

Product overview:

The equipment is complied with BS EN 12983-1 clause 8.4.2 ,8.4.3 and Appendix K. The device uses the pencil nib to compare the scratch resistance of the coating; Apply 4&8N pressure to the pencil, insert the pen core into the hole where the hole is 45° , then the pencil nib completely touches the bottom coating of the pot, and then draw a 2~5cm line on the coating; Judge the effect by the lines drawn.

The pencil hardness test apparatus for exterior organic coatings is a specialized device used to assess the hardness and scratch resistance of coatings applied to exterior surfaces, such as paints, varnishes, and protective coatings. The test determines the ability of the coating to resist the penetration and scratching of a pencil under controlled conditions. Here are the key features and components typically found in a pencil hardness test apparatus:

Test Panel Holder: The apparatus includes a test panel holder that securely holds the coated sample during the test. The holder ensures proper positioning and stability of the panel to ensure consistent and accurate results.

Pencil Holder: The pencil holder or clamp securely holds the pencil in place during the test. It ensures that the pencil is at a specified angle and is in contact with the coating surface during the test.

Test Procedure Guide: The apparatus may include a test procedure guide that provides instructions on how to conduct the pencil hardness test correctly. It outlines the specific testing parameters, such as the angle of the pencil, the applied force, and the number of passes over the coating surface.

Force Application Mechanism: The apparatus incorporates a mechanism to apply a controlled force on the pencil as it moves across the coating surface. This mechanism ensures consistent force application during the test, allowing for accurate comparisons between different coatings.

Result Evaluation: After conducting the test, the apparatus enables the evaluation of the test results. Typically, the test panel is visually inspected for any visible scratches or marks caused by the pencil. The hardness of the coating is determined based on the pencil grade that produces the first visible scratch.

Data Recording and Analysis: The apparatus may have data recording and analysis capabilities to document the test results. This can include recording the pencil grade used, the observed scratches, and any additional information relevant to the evaluation of the coating's hardness.

The pencil hardness test apparatus is widely used in the coatings industry to assess the scratch resistance and hardness of exterior organic coatings. By subjecting the coating to controlled pencil abrasion, this test helps manufacturers and quality control departments evaluate the performance and durability of coatings under real-world conditions. The test results aid in selecting appropriate coatings for exterior applications and ensuring their long-term protection and aesthetic appeal.

Technical parameters:

1. Power supply: AC220V, 50HZ

2. Test station: 1

3. Drive mode: electric + eccentric wheel mechanism

4. Test speed: 0-10 times/min, adjustable

5. Scratch length: 20~50mm, adjustable, default 25mm

6. Scratch angle:45 °

7. Heating platform DB-2EFS:RT+10°C~420°C±1°C, Platform size:L450*W350mm

8. Test mass: one of each 4N, 8N.

9. Pencil: one of each HB,2H,3H,4H,5H.

10. Overall dimension:WDH=900×500×700mm, Maximum allowable sample Ф400mm.

Main configuration list:

| No. | Content | Quantity | Unit |

| 1 | Scratch Resistance Tester | 1 | Set |

| 2 | Heating platform | 1 | Set |

| 3 | Test mass:4N, 8N | 1 | Set |

| 4 | Pencil | 1 | Set |