|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 20 sets per month |

BS EN 12983-1 Cookware Pouring Test Apparatus For Testing The Leakage Volume Of Cookware

Product information:

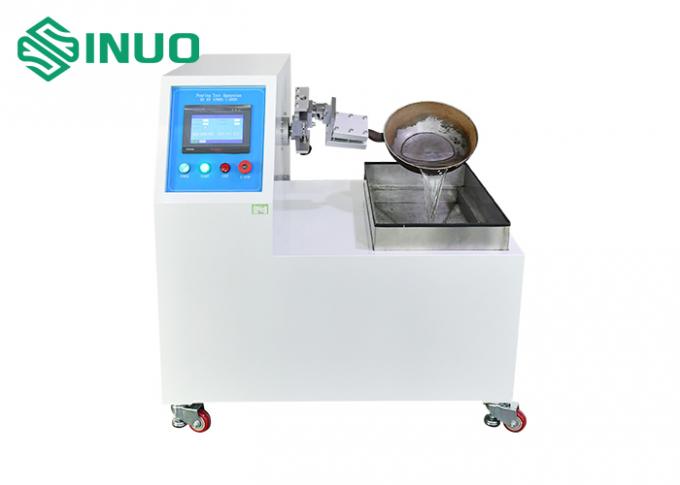

It is used for testing the leakage volume of water from the pouring spout of the cookware.

A cookware pouring test apparatus is a specialized device used to evaluate the pouring performance of cookware, such as pots, pans, kettles, and pitchers. It is designed to simulate the pouring action of liquid contents from the cookware, allowing for the assessment of factors such as accuracy, control, and drip prevention. Here are the key features and components typically found in a cookware pouring test apparatus:

Test Stand: The apparatus includes a stable and adjustable test stand that holds the cookware securely during the pouring test. The stand allows for precise positioning and alignment of the cookware to ensure consistent test conditions.

Liquid Reservoir: The apparatus incorporates a liquid reservoir or container that holds the liquid to be poured. It is typically equipped with a valve or flow control mechanism to regulate the rate of liquid flow during the test.

Pouring Mechanism: The pouring mechanism is the core component of the apparatus and is responsible for simulating the pouring action. It may use a motorized system, gravity, or a combination of both to control the pouring movement. The mechanism should be adjustable to accommodate different sizes and types of cookware.

Flow Measurement: The apparatus may have a flow measurement system to quantify and record the amount of liquid poured during the test. This can be achieved using flow meters, calibrated containers, or weighing scales.

Drip Collection: To evaluate drip prevention, the apparatus may include a drip collection system. This system collects any liquid that drips or spills during the pouring process, allowing for the measurement of drip volumes or frequencies.

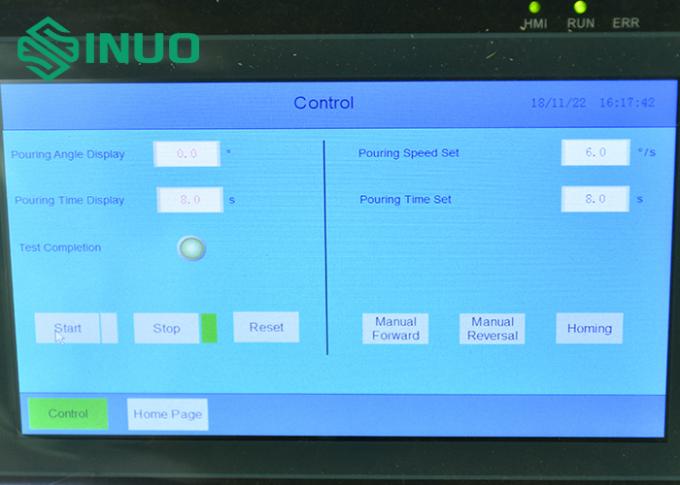

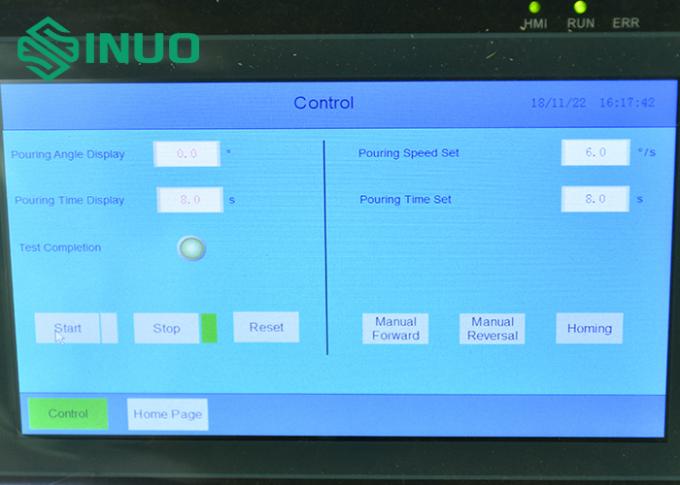

Control Panel: The apparatus is typically equipped with a control panel that enables users to set and adjust various parameters, such as pouring speed, pouring angle, and liquid flow rate. The control panel may also include a timer and other relevant controls.

Data Recording and Analysis: The apparatus may have data recording and analysis capabilities to capture and analyze the test results. This can involve measuring pouring accuracy, quantifying drip volumes, and evaluating the overall pouring performance of the cookware.

Safety Features: Safety considerations are important in the design of the apparatus to protect operators and ensure safe testing procedures. These features may include emergency stop buttons, protective enclosures, and safety interlocks.

The cookware pouring test apparatus is crucial for cookware manufacturers, quality control departments, and researchers to assess and improve the pouring performance of their products. By simulating the pouring action and evaluating factors such as accuracy, control, and drip prevention, this apparatus helps manufacturers optimize the design of cookware for better user experience and functionality.

Applied standard:

The design of the handle torque resistance test apparatus of cookware complies with BS EN 12983-1: 2020 clause 9.1 and Annex L

Features:

Integrated PLC and touch screen control, the test speed , test cycles can be preset,when the preset test cycles have been completed, the test device will stop testing automatically.

Main Specifications:

| Input Power | Match client’s local power supply requirements |

| Control | PLC control, touch screen operation |

| Station | Single station |

| Drive Method | motor-driven |

| Test Speed | 6 °/s |

| Test Cycles | 0-999999, can be preset on touch screen |

Parameter Settings:

Set the pouring speed: 6°/s as required by the standard.

Set time for pouring: set the time for pouring to run, which is used to control half of the water in the cookware.

|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | T/T |

| Supply Capacity: | 20 sets per month |

BS EN 12983-1 Cookware Pouring Test Apparatus For Testing The Leakage Volume Of Cookware

Product information:

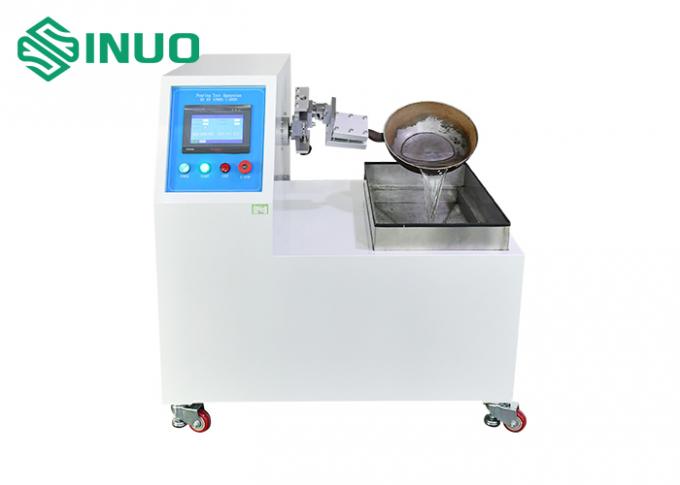

It is used for testing the leakage volume of water from the pouring spout of the cookware.

A cookware pouring test apparatus is a specialized device used to evaluate the pouring performance of cookware, such as pots, pans, kettles, and pitchers. It is designed to simulate the pouring action of liquid contents from the cookware, allowing for the assessment of factors such as accuracy, control, and drip prevention. Here are the key features and components typically found in a cookware pouring test apparatus:

Test Stand: The apparatus includes a stable and adjustable test stand that holds the cookware securely during the pouring test. The stand allows for precise positioning and alignment of the cookware to ensure consistent test conditions.

Liquid Reservoir: The apparatus incorporates a liquid reservoir or container that holds the liquid to be poured. It is typically equipped with a valve or flow control mechanism to regulate the rate of liquid flow during the test.

Pouring Mechanism: The pouring mechanism is the core component of the apparatus and is responsible for simulating the pouring action. It may use a motorized system, gravity, or a combination of both to control the pouring movement. The mechanism should be adjustable to accommodate different sizes and types of cookware.

Flow Measurement: The apparatus may have a flow measurement system to quantify and record the amount of liquid poured during the test. This can be achieved using flow meters, calibrated containers, or weighing scales.

Drip Collection: To evaluate drip prevention, the apparatus may include a drip collection system. This system collects any liquid that drips or spills during the pouring process, allowing for the measurement of drip volumes or frequencies.

Control Panel: The apparatus is typically equipped with a control panel that enables users to set and adjust various parameters, such as pouring speed, pouring angle, and liquid flow rate. The control panel may also include a timer and other relevant controls.

Data Recording and Analysis: The apparatus may have data recording and analysis capabilities to capture and analyze the test results. This can involve measuring pouring accuracy, quantifying drip volumes, and evaluating the overall pouring performance of the cookware.

Safety Features: Safety considerations are important in the design of the apparatus to protect operators and ensure safe testing procedures. These features may include emergency stop buttons, protective enclosures, and safety interlocks.

The cookware pouring test apparatus is crucial for cookware manufacturers, quality control departments, and researchers to assess and improve the pouring performance of their products. By simulating the pouring action and evaluating factors such as accuracy, control, and drip prevention, this apparatus helps manufacturers optimize the design of cookware for better user experience and functionality.

Applied standard:

The design of the handle torque resistance test apparatus of cookware complies with BS EN 12983-1: 2020 clause 9.1 and Annex L

Features:

Integrated PLC and touch screen control, the test speed , test cycles can be preset,when the preset test cycles have been completed, the test device will stop testing automatically.

Main Specifications:

| Input Power | Match client’s local power supply requirements |

| Control | PLC control, touch screen operation |

| Station | Single station |

| Drive Method | motor-driven |

| Test Speed | 6 °/s |

| Test Cycles | 0-999999, can be preset on touch screen |

Parameter Settings:

Set the pouring speed: 6°/s as required by the standard.

Set time for pouring: set the time for pouring to run, which is used to control half of the water in the cookware.