| MOQ: | 1 Set |

| Price: | Negotiable |

| Standard Packaging: | Standard Exporting Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 10 Sets / Month |

IEC 1251 Constant Temperature And Humidity Chamber With PLC Control For Solar Panel Test

Product Information For Temperature And Humidity Walk-In Test Equipment:

Solar panel walk-in constant temperature and humidity test chamber is mainly designed and manufactured according to standards of IEC 60068-2-78, IEC 1251:1993, IEC 61730 and etc. It is used to test photovoltaic modules and determine the ability of modules to withstand long-term moisture penetration. The purpose is to determine the ability of modules to resist heat cycles and humidity-heat tests. It is also suitable for ESS high and low temperature cyclic stress screening test or constant test for electrical and electronic products and other products, parts and materials, and for quality and reliability testing of products, parts and materials under simulated temperature changes.

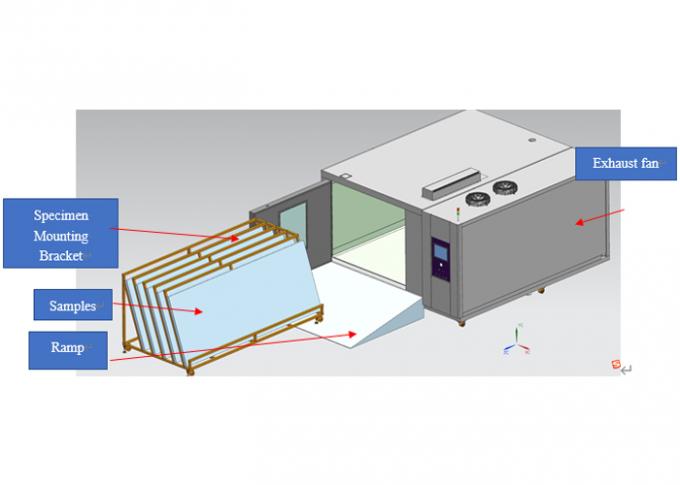

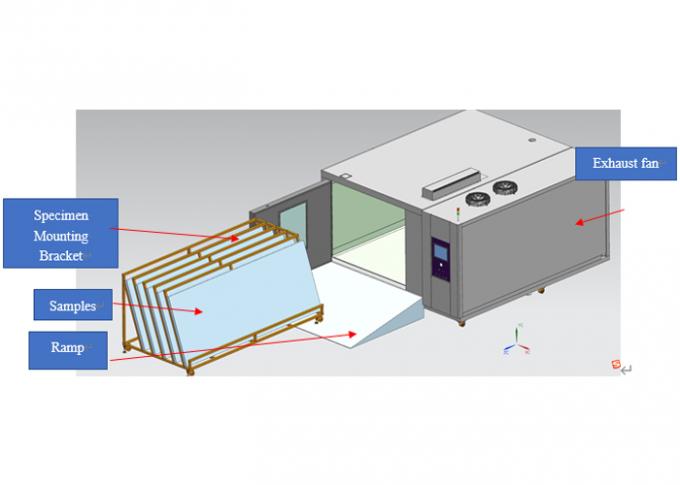

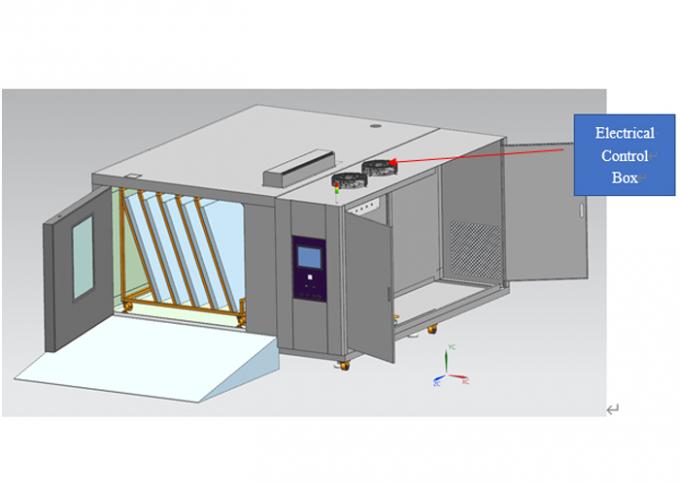

The test room adopts PLC intelligent central integrated control, touch screen display and operation, it is equipped with sample placement brackets, and a slope at the entrance of the test room. The samples are convenient to be moved and placed. The whole system is simple to operate, and the whole machine is beautiful and generous.

System Principle For Temperature And Humidity Walk-In Test Equipment:

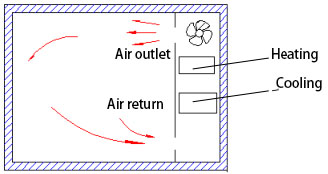

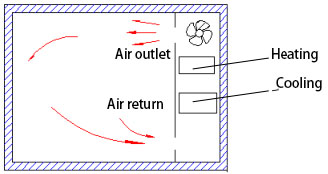

The PLC is used to control the cooling of the compressor, the heating of the heat pipe and the humidification of the humidifier, cooperating with the indoor air duct to realize the control of the temperature and humidity in the chamber.

Forced circulation ventilation, balance temperature regulation method. The control system controls the output of the heater through the PID automatic calculation output according to the temperature point set by the system, and finally reaches a dynamic balance.

Technical Parameter For Temperature And Humidity Walk-In Test Equipment:

| Item | Specifications | |||

| Name | Solar Panel Walk-in Constant Temperature and Humidity Test Chamber | |||

| Model | SN886-6000 | |||

| Working studio size (mm) | 1500×2600×1500 W*D*H | |||

| Numbers of samples that can be placed | 5 pcs, Sample size not larger than 1200×2400×45 mm W*D*H | |||

| Chamber external size(mm) | Approx.2000×2850×2720 W*D*H | |||

| Test Range | Temperature | -40℃~+100℃ | ||

| Humidity |

20%~98%RH (Shown as following)

|

|||

| Heating and cooling rate | Rising rate | ≤1.6℃/min (full average) | ||

| Cooling rate | ≤1.0℃/min (full average) | |||

| Temperature fluctuation | ≤±0.5℃ (at steady state) | |||

| Temperature uniformity | ≤2℃ (at steady state) | |||

| Temperature deviation | ±2.0℃ | |||

| Humidity Deviation |

≤+2/-3%R.H. (when the humidity>75%R.H.) ≤±5%R.H. (when the humidity>≤75%R.H.) |

|||

| Test contents | 1. Thermal cycle: cycle from -40°C±2.0°C to 85°C±2.0°C, the temperature change rate is less than 100°C/h, the constant temperature time is at least 10min, and one cycle does not exceed 6h | |||

| 2. Humidity-heat test: 85°C±2.0°C, 85%±5%, test time 1000h | ||||

| Noise | ≤75dB | |||

| Weight | Approx. 2100KG | |||

| Test method applied |

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT” IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT” IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT” IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle), IDT” |

|||

| Note: The above performance indicators are measured at room temperature +25°C without samples. | ||||

| Material | Inner wall material | SUS304# stainless steel plate | ||

| Outer wall material | Cold rolled steel plate, pickling and phosphating advanced powder baking paint | |||

| Insulation material | rigid polyurethane foam + glass fiber | |||

| Structure | Air duct parts | Centrifugal fan; the air outlet can adjust the air volume, height and return air volume | ||

| Door | Single open door, with handle-type non-reaction handle, the door is equipped with an observation window, lighting lamp, window/door frame anti-condensation electric heating device, Door size: SN886-4300: (approx.) 1.1*1.5M, SN886-5800 (approx.) 1.5*1.5M | |||

| Observation window | The door with one conductive film explosion-proof tempered glass observation window (with anti-condensation function), window size: 500W×600H (mm) | |||

| Fan | Long axis centrifugal fan | |||

| Sample mounting rack | Will be customized to match client’s sample | |||

| Impeller | Use stainless steel impeller imported from Taiwan | |||

| Heater | Nickel-chromium alloy electric heater | |||

| Refrigeration Compressor | French Tecumseh compressor | |||

|

Evaporator

|

Fin type evaporator | |||

| Refrigerating method | Mechanical compressor cascade | |||

| Cooling method | Air-cooling | |||

| Temperature control instrument | 10-inch smart LCD touch programmable controller | |||

| Lead hole | Φ100mm, 1 pc, equipped with a special foam rubber plug (located on the left side of the chamber) | |||

Program Control System For Temperature And Humidity Walk-In Test Equipment:

| Controller | 10-inch smart LCD touch programmable controller |

| Temperature and humidity display accuracy | 0.01℃/ 0.1%RH |

| Touch-type high-resolution screen | Arbitrary setting of fixed conditions, program conditions, and setting of curing test name, serial number, etc. |

| Time range can be set | 0—999H59min |

| Programmable mode | At the same time, 120 groups of programs with different conditions can be set. In any group of programs, it can be divided into 1200 segments, and part of the number of segments can be intercepted arbitrarily to execute the cycle, or to perform cycle work of any section or group. |

| Safety | It has a power-off memory device, which can continue to execute the remaining programs when the power is restored, and can be used as a machine appointment to execute the startup and machine running time. |

| Control | The temperature rise and fall can be used for slope control, curve control, and have the function of self-correcting temperature and humidity reference points. It has the function of PID automatic calculation, which can reduce the convenience caused by manual setting. |

|

Communication function (Optional, cost is additional) |

U disk interface, RS-232 interface, misoperation hardware lock (LOCK), computer communication software is provided |

| Setting | Settings and all conditions are automatically locked by microcomputer |

| Alarm | If an error occurs during setting or operation, a warning signal will be provided |

| Output | The controller has a recording signal port output, which can be connected to a temperature and humidity recorder and can output recording curves |

| Interface | Equipped with standard RS-232 communication interface, long transmission distance, can be connected to PC for control and recording. |

Chamber structure For Temperature And Humidity Walk-In Test Equipment:

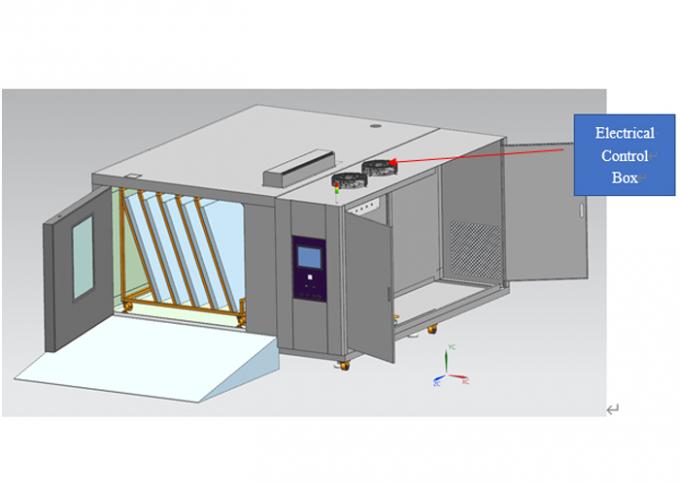

The test chamber consists of a control cabinet, a chamber body, a sample mounting bracket and a slope.

| MOQ: | 1 Set |

| Price: | Negotiable |

| Standard Packaging: | Standard Exporting Plywood Case |

| Delivery Period: | 30 days |

| Payment Method: | T/T |

| Supply Capacity: | 10 Sets / Month |

IEC 1251 Constant Temperature And Humidity Chamber With PLC Control For Solar Panel Test

Product Information For Temperature And Humidity Walk-In Test Equipment:

Solar panel walk-in constant temperature and humidity test chamber is mainly designed and manufactured according to standards of IEC 60068-2-78, IEC 1251:1993, IEC 61730 and etc. It is used to test photovoltaic modules and determine the ability of modules to withstand long-term moisture penetration. The purpose is to determine the ability of modules to resist heat cycles and humidity-heat tests. It is also suitable for ESS high and low temperature cyclic stress screening test or constant test for electrical and electronic products and other products, parts and materials, and for quality and reliability testing of products, parts and materials under simulated temperature changes.

The test room adopts PLC intelligent central integrated control, touch screen display and operation, it is equipped with sample placement brackets, and a slope at the entrance of the test room. The samples are convenient to be moved and placed. The whole system is simple to operate, and the whole machine is beautiful and generous.

System Principle For Temperature And Humidity Walk-In Test Equipment:

The PLC is used to control the cooling of the compressor, the heating of the heat pipe and the humidification of the humidifier, cooperating with the indoor air duct to realize the control of the temperature and humidity in the chamber.

Forced circulation ventilation, balance temperature regulation method. The control system controls the output of the heater through the PID automatic calculation output according to the temperature point set by the system, and finally reaches a dynamic balance.

Technical Parameter For Temperature And Humidity Walk-In Test Equipment:

| Item | Specifications | |||

| Name | Solar Panel Walk-in Constant Temperature and Humidity Test Chamber | |||

| Model | SN886-6000 | |||

| Working studio size (mm) | 1500×2600×1500 W*D*H | |||

| Numbers of samples that can be placed | 5 pcs, Sample size not larger than 1200×2400×45 mm W*D*H | |||

| Chamber external size(mm) | Approx.2000×2850×2720 W*D*H | |||

| Test Range | Temperature | -40℃~+100℃ | ||

| Humidity |

20%~98%RH (Shown as following)

|

|||

| Heating and cooling rate | Rising rate | ≤1.6℃/min (full average) | ||

| Cooling rate | ≤1.0℃/min (full average) | |||

| Temperature fluctuation | ≤±0.5℃ (at steady state) | |||

| Temperature uniformity | ≤2℃ (at steady state) | |||

| Temperature deviation | ±2.0℃ | |||

| Humidity Deviation |

≤+2/-3%R.H. (when the humidity>75%R.H.) ≤±5%R.H. (when the humidity>≤75%R.H.) |

|||

| Test contents | 1. Thermal cycle: cycle from -40°C±2.0°C to 85°C±2.0°C, the temperature change rate is less than 100°C/h, the constant temperature time is at least 10min, and one cycle does not exceed 6h | |||

| 2. Humidity-heat test: 85°C±2.0°C, 85%±5%, test time 1000h | ||||

| Noise | ≤75dB | |||

| Weight | Approx. 2100KG | |||

| Test method applied |

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT” IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT” IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT” IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle), IDT” |

|||

| Note: The above performance indicators are measured at room temperature +25°C without samples. | ||||

| Material | Inner wall material | SUS304# stainless steel plate | ||

| Outer wall material | Cold rolled steel plate, pickling and phosphating advanced powder baking paint | |||

| Insulation material | rigid polyurethane foam + glass fiber | |||

| Structure | Air duct parts | Centrifugal fan; the air outlet can adjust the air volume, height and return air volume | ||

| Door | Single open door, with handle-type non-reaction handle, the door is equipped with an observation window, lighting lamp, window/door frame anti-condensation electric heating device, Door size: SN886-4300: (approx.) 1.1*1.5M, SN886-5800 (approx.) 1.5*1.5M | |||

| Observation window | The door with one conductive film explosion-proof tempered glass observation window (with anti-condensation function), window size: 500W×600H (mm) | |||

| Fan | Long axis centrifugal fan | |||

| Sample mounting rack | Will be customized to match client’s sample | |||

| Impeller | Use stainless steel impeller imported from Taiwan | |||

| Heater | Nickel-chromium alloy electric heater | |||

| Refrigeration Compressor | French Tecumseh compressor | |||

|

Evaporator

|

Fin type evaporator | |||

| Refrigerating method | Mechanical compressor cascade | |||

| Cooling method | Air-cooling | |||

| Temperature control instrument | 10-inch smart LCD touch programmable controller | |||

| Lead hole | Φ100mm, 1 pc, equipped with a special foam rubber plug (located on the left side of the chamber) | |||

Program Control System For Temperature And Humidity Walk-In Test Equipment:

| Controller | 10-inch smart LCD touch programmable controller |

| Temperature and humidity display accuracy | 0.01℃/ 0.1%RH |

| Touch-type high-resolution screen | Arbitrary setting of fixed conditions, program conditions, and setting of curing test name, serial number, etc. |

| Time range can be set | 0—999H59min |

| Programmable mode | At the same time, 120 groups of programs with different conditions can be set. In any group of programs, it can be divided into 1200 segments, and part of the number of segments can be intercepted arbitrarily to execute the cycle, or to perform cycle work of any section or group. |

| Safety | It has a power-off memory device, which can continue to execute the remaining programs when the power is restored, and can be used as a machine appointment to execute the startup and machine running time. |

| Control | The temperature rise and fall can be used for slope control, curve control, and have the function of self-correcting temperature and humidity reference points. It has the function of PID automatic calculation, which can reduce the convenience caused by manual setting. |

|

Communication function (Optional, cost is additional) |

U disk interface, RS-232 interface, misoperation hardware lock (LOCK), computer communication software is provided |

| Setting | Settings and all conditions are automatically locked by microcomputer |

| Alarm | If an error occurs during setting or operation, a warning signal will be provided |

| Output | The controller has a recording signal port output, which can be connected to a temperature and humidity recorder and can output recording curves |

| Interface | Equipped with standard RS-232 communication interface, long transmission distance, can be connected to PC for control and recording. |

Chamber structure For Temperature And Humidity Walk-In Test Equipment:

The test chamber consists of a control cabinet, a chamber body, a sample mounting bracket and a slope.