|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Standard Exporting Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 20 Sets Per Month |

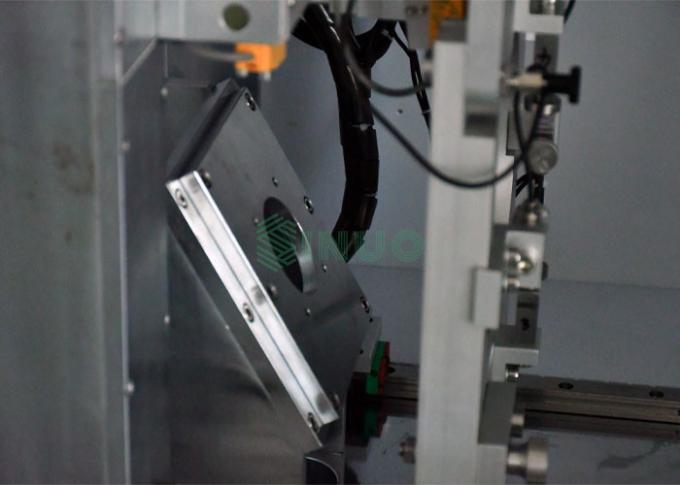

IEC 62196 Misalignment Test Apparatus for Electric Vehicle Accessories

Product Information:

This misalignment test apparatus conforms to IEC62196-3 clause 36.3, figure 18.

During temperature rise test, immediately following temperature stabilization, the accessories are subjected to external mechanical loads as illustrated in Figure 18.

Using a force gauge, apply a load of 100 N with a tolerance of -0/+10 N as illustrated in Figure 19 in each direction. The load should be applied for a minimum of 1 min. Following this load application, the load should be removed for a time of 10 s and the load re-applied in the next direction within 10 s. This process is continued until the load is applied in the 4 directions (-X, +X, -Y, +Y) as illustrated in Figure 19.

The equipment adopts X, Y (Figure 19) sliding table, driven by servo motor and monitored by force value sensor. When the force value reaches the required time for automatic constant force holding, it will automatically switch to another direction for test.

Technical Parameters:

| Power | AC220V, 60Hz |

| Control Method | PLC control, touch screen operation |

| Station | One |

| Drive Mode | servo motor, two pcs, X and Y |

| Force | 0-500N |

| Force holding time | 0-999.9s |

| Interval time | 0-999.9s |

| Force application direction | -X, +X, -Y, +Y |

| Specimen mounting bracket | 30 ° slope, 1000mm height from the ground |

| Overall dimensions of equipment | 100mm×400mm×1500mm,150kg |

|

|

| MOQ: | 1 |

| Price: | Negotiable |

| Standard Packaging: | Standard Exporting Plywood Case |

| Delivery Period: | 30 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 20 Sets Per Month |

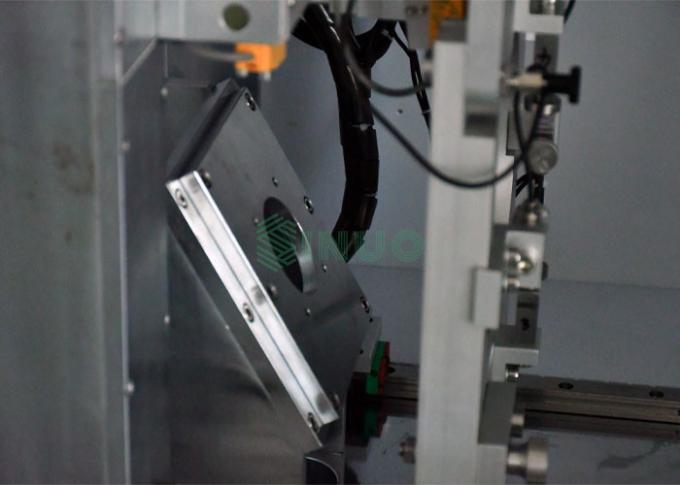

IEC 62196 Misalignment Test Apparatus for Electric Vehicle Accessories

Product Information:

This misalignment test apparatus conforms to IEC62196-3 clause 36.3, figure 18.

During temperature rise test, immediately following temperature stabilization, the accessories are subjected to external mechanical loads as illustrated in Figure 18.

Using a force gauge, apply a load of 100 N with a tolerance of -0/+10 N as illustrated in Figure 19 in each direction. The load should be applied for a minimum of 1 min. Following this load application, the load should be removed for a time of 10 s and the load re-applied in the next direction within 10 s. This process is continued until the load is applied in the 4 directions (-X, +X, -Y, +Y) as illustrated in Figure 19.

The equipment adopts X, Y (Figure 19) sliding table, driven by servo motor and monitored by force value sensor. When the force value reaches the required time for automatic constant force holding, it will automatically switch to another direction for test.

Technical Parameters:

| Power | AC220V, 60Hz |

| Control Method | PLC control, touch screen operation |

| Station | One |

| Drive Mode | servo motor, two pcs, X and Y |

| Force | 0-500N |

| Force holding time | 0-999.9s |

| Interval time | 0-999.9s |

| Force application direction | -X, +X, -Y, +Y |

| Specimen mounting bracket | 30 ° slope, 1000mm height from the ground |

| Overall dimensions of equipment | 100mm×400mm×1500mm,150kg |