| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood |

| Delivery Period: | 1 Month |

| Payment Method: | L/C, T/T, Western Union, MoneyGram |

| Supply Capacity: | 20 Sets Per Month |

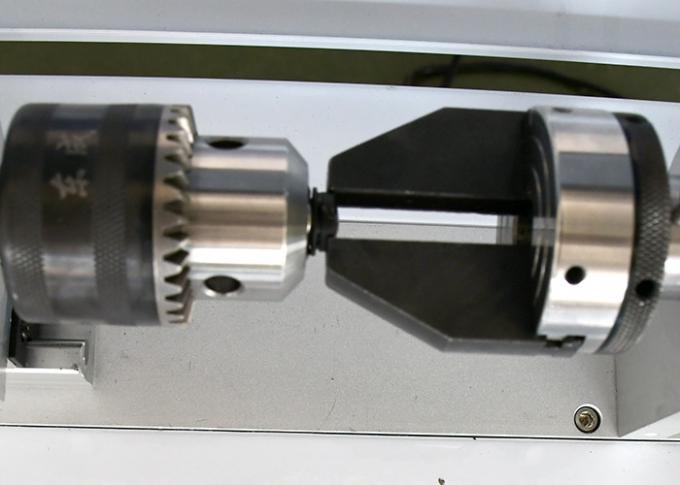

Camera Lens Rotating Torque Testing Equipment

Product overview:

The testing machine is designed and manufactured strictly according to customer's specific requirements. It is driven by Panasonic servo motor, equipped with Mitsubishi PLC, 7-inch touch screen. It is a dedicated high-end torque test equipment with threaded lens sleeve.

This testing machine is mainly used to verify the thread torsion strength of the lens with a threaded lens sleeve, and verify its fatigue resistance after a certain number of rotation.

Working principle:

Use a servo motor to drive the fixture holding the lens to rotate a certain number of times N (N=thread length*10/thread pitch) at a speed of not less than 20 times/min, and insert it into the corresponding threaded sleeve. The cylinder can bear a torque greater than 1.2kgf*cm through a combination of fixed pulleys and weights.

Technical Parameters:

|

No.: |

Item |

Specifications |

|

1 |

Input power supply | Can be customized |

|

2 |

Electrical control | PLC |

|

3 |

Operation |

7” color touch screen |

|

4 |

Drive |

Panasonic servo motor |

|

5 |

Test station |

1 |

|

6 |

Clockwise Counterclockwise rotation cycles | 0-999999, can be preset |

|

7 |

Rotation speed | 10-30 cycles /min |

|

8 |

Sleeve thread specification | Provided by client |

|

9 |

Fixture out diameter for sleeve | 40mm (The radius of the torque wheel is 20mm) |

|

10 |

Weight for torque | 10N (Achieve torque 0.2N.m, greater than 1.2kgf*cm), other weights can be customized |

|

11 |

Fixture type |

Two types of external clamping and pin clamping, hardness ≥HRC28, smoothness higher than Ra3.2, suitable for specimens with a maximum outer diameter of less than 40mm |

| MOQ: | 1 |

| Price: | Customized |

| Standard Packaging: | Plywood |

| Delivery Period: | 1 Month |

| Payment Method: | L/C, T/T, Western Union, MoneyGram |

| Supply Capacity: | 20 Sets Per Month |

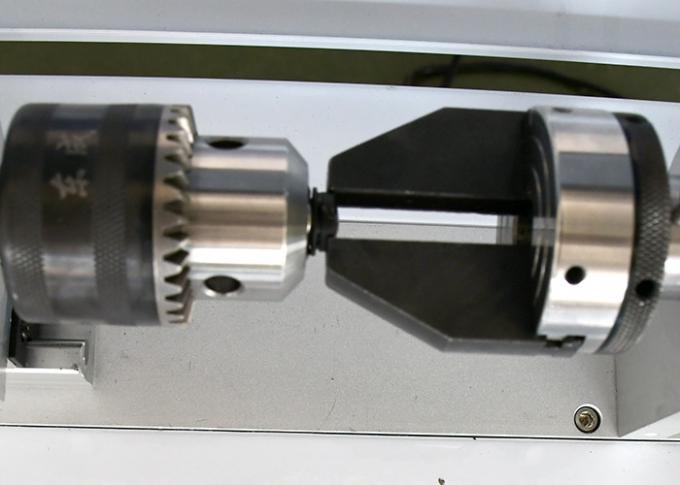

Camera Lens Rotating Torque Testing Equipment

Product overview:

The testing machine is designed and manufactured strictly according to customer's specific requirements. It is driven by Panasonic servo motor, equipped with Mitsubishi PLC, 7-inch touch screen. It is a dedicated high-end torque test equipment with threaded lens sleeve.

This testing machine is mainly used to verify the thread torsion strength of the lens with a threaded lens sleeve, and verify its fatigue resistance after a certain number of rotation.

Working principle:

Use a servo motor to drive the fixture holding the lens to rotate a certain number of times N (N=thread length*10/thread pitch) at a speed of not less than 20 times/min, and insert it into the corresponding threaded sleeve. The cylinder can bear a torque greater than 1.2kgf*cm through a combination of fixed pulleys and weights.

Technical Parameters:

|

No.: |

Item |

Specifications |

|

1 |

Input power supply | Can be customized |

|

2 |

Electrical control | PLC |

|

3 |

Operation |

7” color touch screen |

|

4 |

Drive |

Panasonic servo motor |

|

5 |

Test station |

1 |

|

6 |

Clockwise Counterclockwise rotation cycles | 0-999999, can be preset |

|

7 |

Rotation speed | 10-30 cycles /min |

|

8 |

Sleeve thread specification | Provided by client |

|

9 |

Fixture out diameter for sleeve | 40mm (The radius of the torque wheel is 20mm) |

|

10 |

Weight for torque | 10N (Achieve torque 0.2N.m, greater than 1.2kgf*cm), other weights can be customized |

|

11 |

Fixture type |

Two types of external clamping and pin clamping, hardness ≥HRC28, smoothness higher than Ra3.2, suitable for specimens with a maximum outer diameter of less than 40mm |