As the popularity of electric vehicles continues to rise, there is an increasing demand for reliable and durable vehicle connectors and plugs that can withstand the stresses of daily use. To ensure that these components meet the necessary performance standards, it is important to subject them to rigorous testing.

One crucial aspect of this testing involves evaluating the durability of vehicle connectors and plugs under real-world conditions, such as those encountered during use in parking lots or other areas where vehicles may drive over them. To accomplish this, a specialized testing apparatus known as a vehicle drive over testing apparatus has been developed.

The test equipment is used to check whether a plug or vehicle connector shall have adequate resistance to damage from being driven over by a vehicle, unless it is provided with a cable management system which prevents the accessory from being left on the ground.

Accessories wired with the minimum size cable of a type recommended by the manufacturer shall be placed on a concrete floor in any normal position of rest. A crushing force of (5000±250) N or (11000±550) N shall be applied by a conventional automotive tire, P225/75R15 or an equivalent tire suitable for the load, mounted on a steel rim and inflated to a pressure of (2.2±0.1) bar. The wheel is to be rolled over the vehicle connector or plug at a speed of (8±2) km/h. The accessory is to be oriented in a natural resting position before applying the force in a different direction for each sample. The accessory under test shall be held or blocked in a fixed position so that it does not move substantially during the application of the applied force. In no case is the force to be applied to the projecting pins.

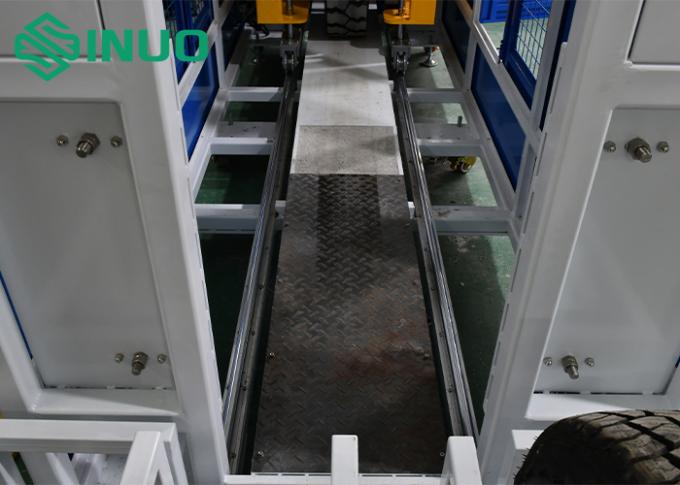

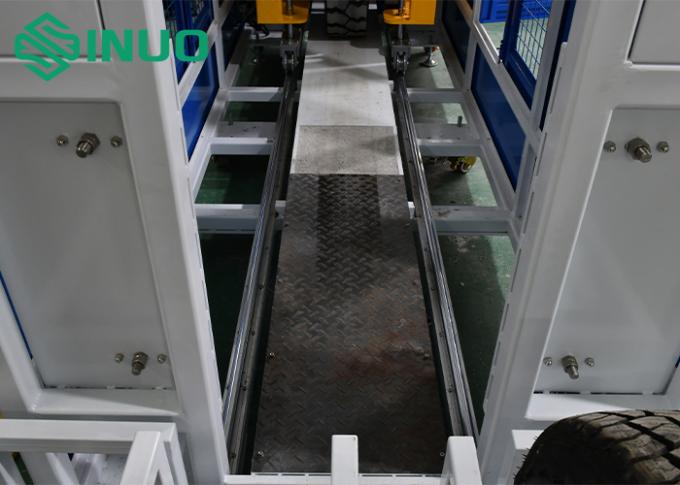

A. The equipment chassis is treated with a protective cover to ensure the safety of the test process; the bottom of the chassis is equipped with a shock-absorbing foot pad and a pulley structure for easy installation and disassembly. The rolling test is achieved by heavy-duty rails guiding, roller set sliding, high-power servo motor combined with the turbine reducer driving the spindle to reach the test speed. The sample fixing sliding device is equipped with a function box mounting jig, and the jig is universally adjustable (it can be adjusted up and down, left and right according to the size and shape of the specimen).

B. The crushing force adjusting device is designed as an up-and-down adjustable structure. The tires subjected to the specimen, the upper and lower sliding frames and the power system and the counterweight are the required test weight as a whole, equipped with an imported precision force sensor; fine-tuning each applied force, and the force is reset to zero automatically after the tire contacts sample is adjusted, the force value is redisplayed; thus, ensuring the force accuracy of each test.

C. The equipment adopts the working mode of front and rear driving of the tire (the direction of rolling is driven by the positive and negative rotation of the servo motor), keeping the sample fixed, achieve the most realistic simulation of the reciprocating rolling of the automobile tire, thus effectively carrying out simulated crushing on the specimen.

D. The main unit consists of PLC control, touch screen, casters and connecting lines, easy movement and connection.

The results of our testing demonstrate the effectiveness of the apparatus in providing a robust evaluation of the durability and performance of these critical components.

As the popularity of electric vehicles continues to rise, there is an increasing demand for reliable and durable vehicle connectors and plugs that can withstand the stresses of daily use. To ensure that these components meet the necessary performance standards, it is important to subject them to rigorous testing.

One crucial aspect of this testing involves evaluating the durability of vehicle connectors and plugs under real-world conditions, such as those encountered during use in parking lots or other areas where vehicles may drive over them. To accomplish this, a specialized testing apparatus known as a vehicle drive over testing apparatus has been developed.

The test equipment is used to check whether a plug or vehicle connector shall have adequate resistance to damage from being driven over by a vehicle, unless it is provided with a cable management system which prevents the accessory from being left on the ground.

Accessories wired with the minimum size cable of a type recommended by the manufacturer shall be placed on a concrete floor in any normal position of rest. A crushing force of (5000±250) N or (11000±550) N shall be applied by a conventional automotive tire, P225/75R15 or an equivalent tire suitable for the load, mounted on a steel rim and inflated to a pressure of (2.2±0.1) bar. The wheel is to be rolled over the vehicle connector or plug at a speed of (8±2) km/h. The accessory is to be oriented in a natural resting position before applying the force in a different direction for each sample. The accessory under test shall be held or blocked in a fixed position so that it does not move substantially during the application of the applied force. In no case is the force to be applied to the projecting pins.

A. The equipment chassis is treated with a protective cover to ensure the safety of the test process; the bottom of the chassis is equipped with a shock-absorbing foot pad and a pulley structure for easy installation and disassembly. The rolling test is achieved by heavy-duty rails guiding, roller set sliding, high-power servo motor combined with the turbine reducer driving the spindle to reach the test speed. The sample fixing sliding device is equipped with a function box mounting jig, and the jig is universally adjustable (it can be adjusted up and down, left and right according to the size and shape of the specimen).

B. The crushing force adjusting device is designed as an up-and-down adjustable structure. The tires subjected to the specimen, the upper and lower sliding frames and the power system and the counterweight are the required test weight as a whole, equipped with an imported precision force sensor; fine-tuning each applied force, and the force is reset to zero automatically after the tire contacts sample is adjusted, the force value is redisplayed; thus, ensuring the force accuracy of each test.

C. The equipment adopts the working mode of front and rear driving of the tire (the direction of rolling is driven by the positive and negative rotation of the servo motor), keeping the sample fixed, achieve the most realistic simulation of the reciprocating rolling of the automobile tire, thus effectively carrying out simulated crushing on the specimen.

D. The main unit consists of PLC control, touch screen, casters and connecting lines, easy movement and connection.

The results of our testing demonstrate the effectiveness of the apparatus in providing a robust evaluation of the durability and performance of these critical components.